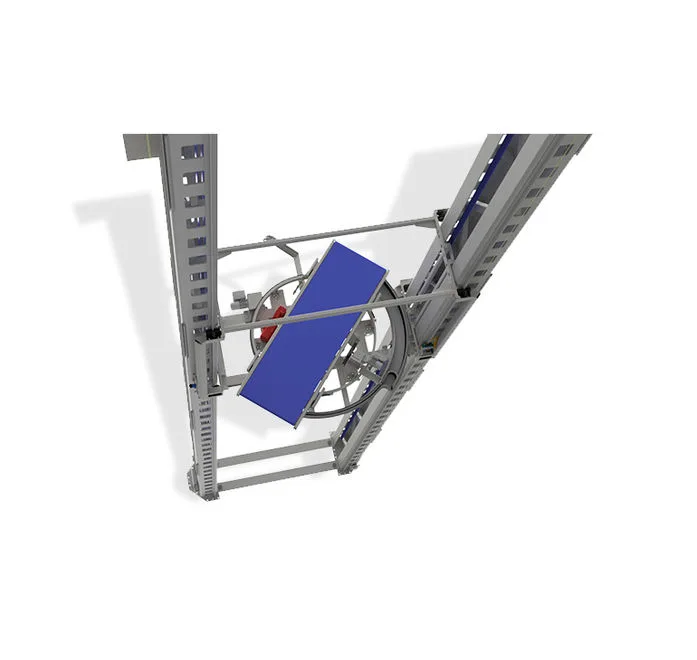

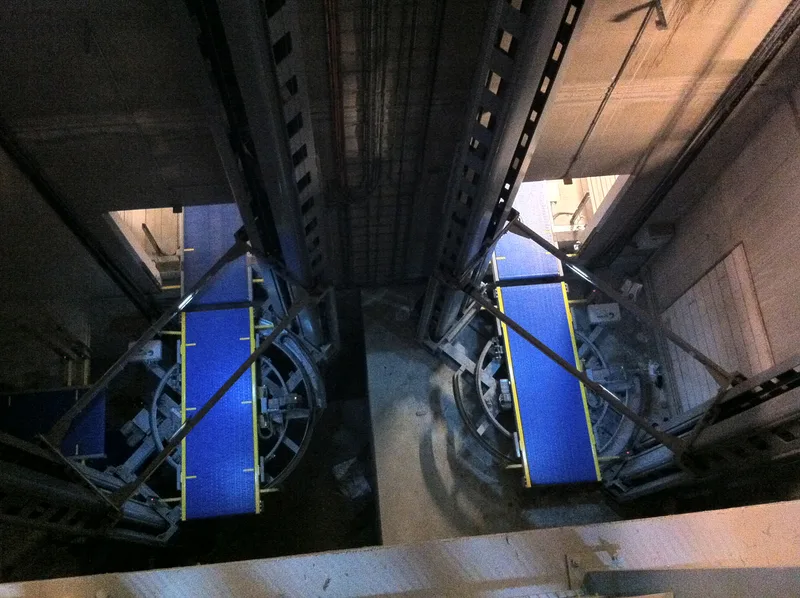

Vertical conveyor for pallets

Up to 2500 kilograms can be transported by the vertical conveyor

In internal logistics, product flows must be maintained. To transport goods from top to bottom or vice versa, a vertical conveyor or elevator is an efficient solution. Baust has been specialized in the production of material handling systems and offers customized conveyor systems to transport your goods specifically and effectively to the desired location.

- up to 25 m in height

- with a choice of superstructures single or multi places (roller conveyors, chain conveyors, turn tables …)

- One-, two- or four-stand design

- adjustable speeds, controllable drive concepts

- with anti-fall guard and gap detection

- saves on costly, high-maintenance lifts and forklift trucks

- maintenance-friendly due to ease of access

Specifications

- power: 30 – 100 cycles/h

- lifting height: up to 25 m

- drive: electric motor

- loading and unloading: only via conveyor system

- control mode: automatic

- power supply: 4 kVA – 16A 230/400 V

Pallet loading

- total weight up to 2500 kg

- standard pallet (W x L in mm): 800 – 1200 x 1200

- max. Height incl. Pallet: 2000 mm

- overhang allowed on each side: + – 50 mm

Options

- enclosure and other access protection

- high speed or fire doors

- separation for contribution

Vertical conveyor: transporting pallets safely and quickly

If pallets must be loaded and transported up or down in your operation, the vertical conveyor of Baust is just right for you. This safe and reliable material flow system is available in various designs and can be adjusted to your needs. With the elevator, you can save long transport routes as well as expensive and maintenance-intensive lifts and forklifts. Extra savings include the maintenance. Since elevators for persons are subject to high requirements, the maintenance intervals are more frequently. This does not affect the vertical conveyor of Baust as it is only specialized in the transport of goods.

Often the vertical conveyor can be found in the front area of a high-bay warehouse, but the material flow systems are also suitable for all establishments where pallets must be loaded and transported up or down. This includes automated warehouses, distribution centers and production plants. The elevator connects different levels of a conveying system – without complicated transportation routes.

Request a non-binding offer now

Uncomplicated transport by vertical conveyor

Sophisticated transport systems are essential for smooth warehouse logistics and fast processes in distribution and production centers. While many companies use forklifts or elevators for this, vertical or vertical pallet conveyors have now proven to be very advantageous over the aforementioned. Because the powerful and stable vertical conveyors allow transport over different levels without the high investment as with an elevator system or forklift truck. Pallet conveyor systems are subject to significantly less strict requirements compared to elevators and therefore have to be serviced at much shorter intervals. Nevertheless, transports of up to 2500 kg are no problem for pallet conveyor systems and thanks to fall protection and gap monitoring, your goods and employees are still safe. With a powerful vertical conveyor, your warehouse or distribution center can be increasingly automated and work faster and more reliably thanks to a better material flow.

The pallet conveyor system for your company

What is also special about this pallet conveyor technology is that the systems can be easily adapted to different product flows and storage rooms. Our expertise lies in customer-specific systems for material transport and we can advise you comprehensively on the construction of your individual conveyor systems. The adaptability benefits from the fact that the vertical and vertical conveyors work at a height of up to 25 m, but also with significantly smaller distances between the different storage levels. The superstructures of the pallet conveyor systems can also be single-seat or multi-seat and function as roller conveyors, chain conveyors or turntables. A vertical conveyor is particularly easy to access, but the vertical conveyors are also extremely easy to maintain and intuitive to use. In this way, you can safely do without large investments such as a forklift truck to transport goods. In addition, this type of pallet transport does not require elaborately trained personnel like a forklift truck and you can continue to deploy your employees flexibly.

Optimal use of storage rooms with a vertical conveyor

Another advantage of transporting pallets using conveyor systems is that, thanks to their simple design, they take up little space and can also be used when space is limited. You can use a vertical conveyor to transport pallets with almost any material or product and thus use a uniform system for the entire warehouse. While elevators and forklifts quickly reach their limits as to which products can be transported, the conveyor systems remain flexible. The construction can be done as a single column, double column or four column and the speed can also be easily adjusted. The compact design of the vertical conveyor makes it possible to automate storage rooms with limited capacities and to transport heavy materials with ease. Thanks to the stable steel construction of the vertical and vertical conveyors, you don’t have to worry about stability as long as the maximum capacities are not exceeded.

Durable pallet conveyor systems for a reliable material flow

A principle that becomes apparent after a few empirical values at the latest is that even the most sought-after products do not protect against stagnating sales if the pallet conveyor technology does not function reliably for the goods. In order for the warehouse logistics to achieve its optimum, the use of powerful and innovative technology is necessary. Our vertical conveyors are a fundamental part of smooth pallet transport and process reliability that enable scalable sales. With a pallet conveyor system from our production, you can count on many years of operation without complications thanks to high-quality components. The pallet conveyor can be controlled precisely and safely, and controlled acceleration is not a problem with the vertical conveyor. Let yourself be convinced of the continuous quality and durability of our products.

Individual pallet conveyor systems from professionals

After more than 60 years of experience with conveyor technology and complete systems for industrial needs, we can offer you competent advice and expertise with conviction. Our products are characterized by the fact that they not only increase production capacities without major maintenance or investment, but also help to optimize the entire production process through automation. We are at your side at all times to provide advice and work with you to develop individual concepts for the use of our vertical and vertical conveyors. You benefit from our all-round service and receive all products and services from a single source if you decide to work with us. In this way, you will always receive your pallet conveyor systems on time and with transparent and fair pricing, even for individual and complex inquiries.

Vertical conveyor for optimal internal logistics

If you want to make your product flows modern and powerful, pallet conveyors are the ideal solution. With a vertical conveyor or vertical conveyor, the transport of goods over several levels is no problem at all. If desired, you can even have enclosures or other access protection attached to the conveyor systems for additional security as required. You can also order high-speed gates and fire protection devices in our offer for customer-specific pallet conveyors. A vertical conveyor or vertical conveyor pallets from our company guarantees you a robust system that will function reliably for many years after commissioning with little maintenance. Feel free to contact us for inquiries or advice on our vertical conveyor or other pallet conveyor systems to enable automated warehouses and production centers without complicated measures.