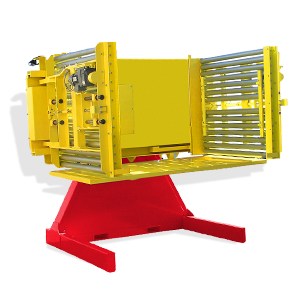

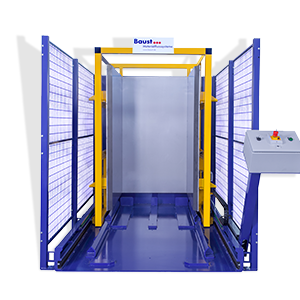

The PW 500 offers the simplest and therefore most economical variant of palletizing and is particularly suitable for pressure-stable and insensitive goods that can withstand a lot.

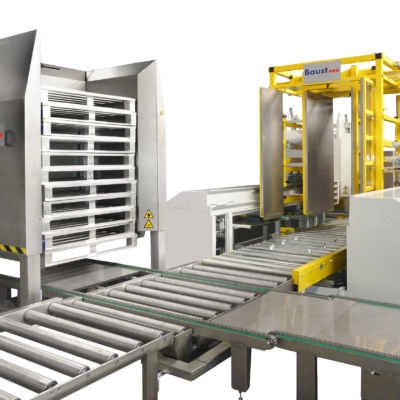

The most efficient solution to get robust and pressure resistant goods from one pallet to another fully automatically. The PW 500 Inline offers the proven clamping method for conveyor lines.

The pallet inverter PW 600 is ideal where robust goods such as e.g. bagged goods or big-bags are involved. Both poor pallet quality and varying sizes of pallet present no problem.

To change or rotate loaded pallets in a fully automated environment, the choice is the PW 600 Inline.

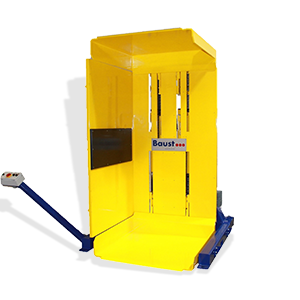

The PW 700 from Baust is particularly suitable for the speedy pallet changing of robust goods such as bags. Also the exchange of damaged pallets presents no problem for the PW 700. Exactly as with the PW 600 this pallet changer applies the inverting ...

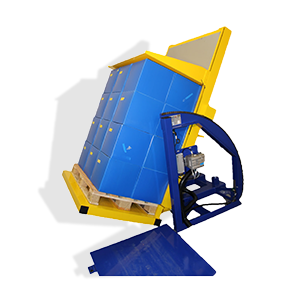

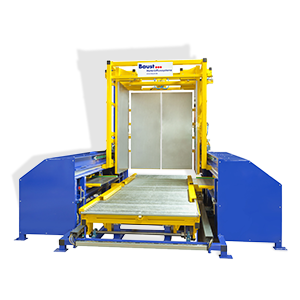

The simplest pallet changer with tilting method is suitable for tilt-stable goods such as cardboard boxes or crates and does not require side walls and pallet clamps due to the 92° angle.

Due to the diagonal tilting process by 90 – 120° into the corner, the PW 800 C does not need side walls. Ideal for space-saving and ergonomic repalletising of loads.

With the PW 800 from Baust, the pallet change is done by a backward tilting movement from 100 to 135°. The pallet changer PW 800 with side walls and pallet clamp is ideal for unsecured loads such as, e.g. drums, sacks or big-bags.

The pallet changer PW 800 Inline offers the fully automatic tilting method as a basic solution. The integration in further conveyor technology with additional components such as pallet magazines or packaging machines is possible quite easily.

Thanks to the tilting angle of up to 180°, there are no more problems with cover sheets or slip sheets. Loose sheets can disrupt the automatic exchange process by falling into the machine or conveyors.

The PW 1000 ensures a precise and smooth operation where exchange of pallets for large and robust goods is frequently necessary. Its particular attributes are the Plug & Play construction and the simple operation.

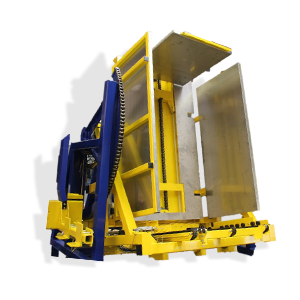

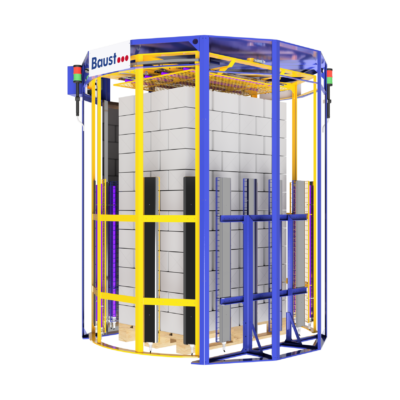

The pallet changer PW 2000 encloses the goods very securely – two flexible side walls together with the rear wall secure the goods from three sides. Additional sliding plates ensure a particularly gentle exchange of pallets of highly sensitive goods....

The PW 3000 from Baust offers a clever two-way solution. The pallet changer allows loading and unloading from both the front and rear of the machine and is often used in clean room airlocks.

The PW 4000 is the extended version of the PW 2000 with conveyor technology. Due to the one-sided infeed and discharge of the pallets, the pusher is predestined for a niche location.

The PW 5000 from Baust can be loaded from both ends and be utilized as a fully automated sluice in clean room areas requiring hygienic separation. This makes the pallet changer indispensable, particularly in the food and pharmaceutical industries.

The PW 6000 from Baust is ideal when large quantities of pallets on which highly sensitive goods is stored have to be exchanged. A one-sided material flow and optimized processes are the basis for the most powerful pallet changer.

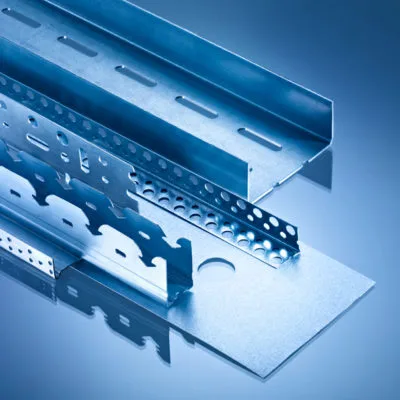

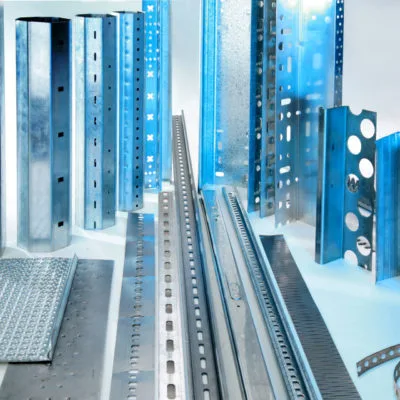

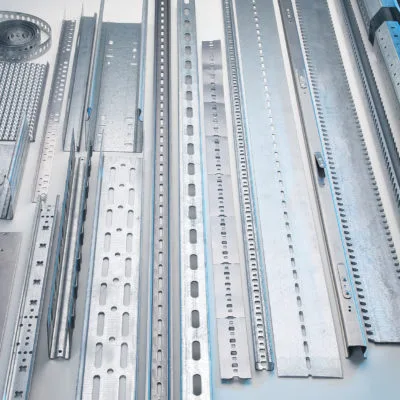

Bauprofile können mit Rotationsstanzmaschinen effizient gefertigt werden. Gerade bei hohen Stückzahlen ist die Technik des Rotationsstanzens unumgänglich.

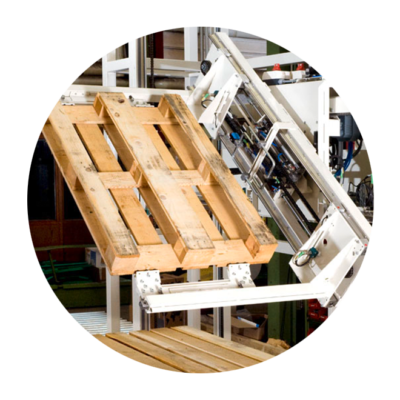

Changing pallets is the focus in the area of pallet handling. Palletizing is used in various ways: e.g. the hygiene reason.

Baust offers a huge number of pallet transport components that guarantee you optimum performance, product care and the highest security. They are constructed with the greatest care for your precise individual needs.

With our drum palletizer and our roller conveyor, you transport your drums extremely economically and, above all, safely. Our particularly safe method using slide plates reliably avoids damage to your drums.

Our material flow systems are optimally applicable for mesh box transport. Extreme weights and the high resistance to wear and tear offer you decisive advantages as regards economic efficiency.

Baust offers you individual transport solutions for transporting long goods. For such challenging special cases, we offer you comprehensive, individual solutions with the highest level of automation and the highest transport security.

High throughput, special transport security and high quality in implementation distinguish our individual container transport solutions.

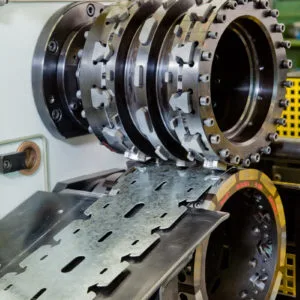

Punching of CW profiles or plaster angle profiles with speeds up to 150 m/min.

Integration within or even as a self-sufficient machine in front of the profiling line.

Continuous punching offers safety in the punching process for shelves and storage profiles.

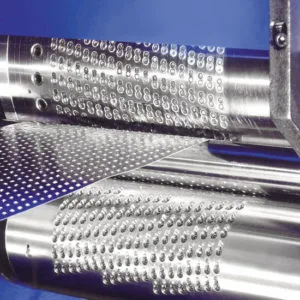

We offer an optimal production of the roller shutter shafts with our rotary punching machines.

Flexible punching machines are required in the area of contract profiles.

DATA PROTECTION - PRIVACY POLICY

| |

1. AN OVERVIEW OF DATA PROTECTION

General

The following gives a simple overview of what happens to your personal information when you visit our website. Personal information is any data with which you...