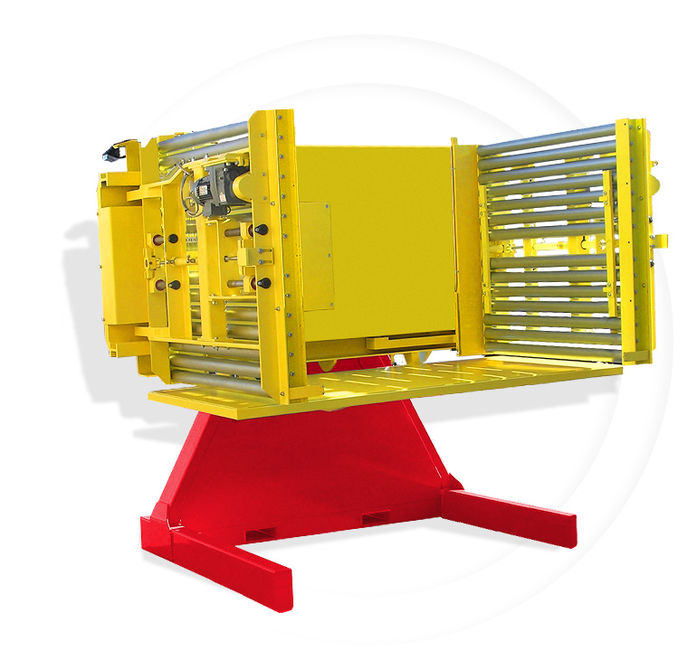

Pallet inverter PW 600 Inline

Fully automatic pallet inverting and changing

Baust pallet inverter using the inverting method offer a lot of advantages: They are leakage-free, low-maintenance, low-noise and suited for many different pallet sizes and qualities. The PW 600 Inline makes it possible to use all these proven qualities of stand-alone PW 600 in a fully automated conveyor line.

- automatic inverting 180°

- ideal for robust goods, particularly bags

- reliable even with poor quality pallets

- many applications: turning, inverting, mixing

- Inline version with various options

- inverter integrated in other conveyors

Specifications

- performance: 10 – 30 changes/h

- dimensions (L x W x H in mm): 2100 x 2400 x 2550

- machine weight: approx. 3500 kg

- clamping, turning & side wall: electrically driven

- loading & unloading: forklift/conveyor technology

- control mode: automatic

- power supply: 4 kVA – 16A 230/400 V R1/2″, 6 bar

Pallet loading

- total weight up to 1500 kg

- pallet dimensions (W x L in mm): 800 x 1200

- height incl. pallet: 1000 – 2000 mm

- goods: e.g. cardboard boxes, bags

- overhang allowed

Options

- goods height > 2000 mm

- other pallet dimensions

changing with the PW 600 Inline

If pallets need to be changed or rotated in an automated system, the choice is the pallet inverter PW 600 Inline. In continuous operation, all steps of the turning process can be done gently and automatically without burdening an employee with the empty pallet handling. The new empty pallet is fixed by the centering of the pallet inverter and turned to the upper position. The loaded pallet then moves into the inverter and is clamped from above and below. This is followed by the 180 ° rotation and the opening of the loading tables. The side door opens and the rotated pallet is unloaded without the source palette.

After this process, the goods stand upside down. If this is not desired, the automated tilting procedure of the PW 800 Inline is an alternative. If the pallet inverter is only used for the 180° turning, the empty pallet, which remains in the inverter, can be directly used again for the next cycle. If pallets have to be exchanged, the empty source pallet must be turned back and transported away via the conveyor system.

We recommend the PW 600 Inline for 30 changes per hour.

Request a non-binding offer now