Pallet inverter

Safe pallet changing in every branch of industry

Do you want to maximize the efficiency of your pallets? Then a pallet inverter from Baust is exactly what you need! With our state-of-the-art products, you can effortlessly turn over your pallets and thus significantly increase the useful life of each pallet. By using a pallet inverter from Baust, you not only save time, but also costs. All of our pallet inverters are manufactured to the highest standards, providing you with a reliable and durable solution to your needs.

Rely on our experience and make your logistics processes even more efficient!

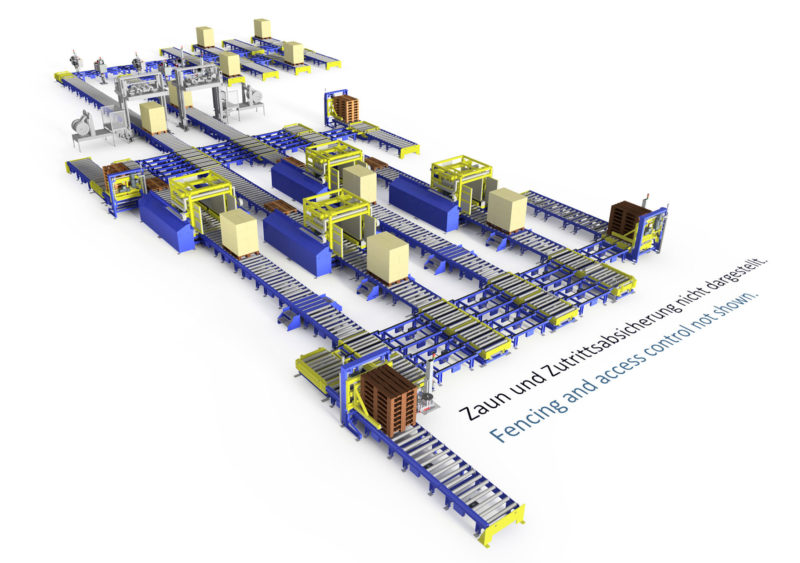

Repalletize processes with pallet inverter

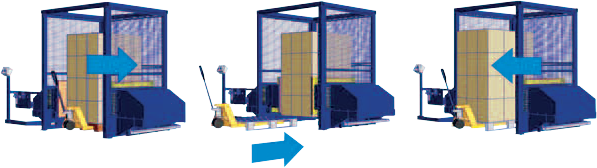

Pallet inverters with the clamping method

Palletize robust goods quickly and cheaply

- Side clamping of the goods

- Simplest and cheapest option for particularly robust goods

- pallet inverting: Ideal for palletizing cardboard boxes and boxes

- Lowering and exchanging the pallet using a hand pallet truck or a lifting roller conveyor

- Performance: up to 50 changes per hour

Pallet changer

PW 500

Pallet changer

PW 500 Inline

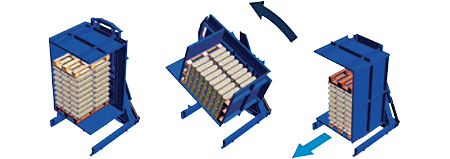

Pallet inverters with the inverting and tilting method

Suitable for many pallet sizes

- Rotate or tilt the goods by 90 to 180°

- Ideal for palletizing sacks and big bags

- Overhang of the goods is not a problem

- Reliable even with poor pallet quality and different pallet dimensions

- Performance: up to 55 changes per hour

Pallet inverter

PW 600

Pallet inverter

PW 600 Inline

Pallet inverter

PW 700

Pallet changer

PW 800 E

Pallet changer

PW 800 C

Pallet changer

PW 800

Pallet changer

PW 800 Inline

Pallet changer

PW 900 Inline

Pallet inverter and the reverse method

The reverse method of a pallet inverter works as follows:

- Loading the pallet: the pallet is loaded into the pallet inverter, either manually by a forklift or automatically by a conveyor belt.

- Securing the load: once the pallet is loaded, it is secured by a hydraulic clamp or pressure plate mechanism. This mechanism holds the pallet and its load securely while the turning operation takes place.

- Turning operation: After the load is secured, the turning operation begins. The pallet inverter lifts and rotates the pallet 180 degrees. Depending on the model and settings, this process can be repeated once or several times.

- Unloading the pallet: After the pallet has been turned, the securing device is released and the pallet can be removed from the pallet inverter.

This method makes it possible to bring the bottom of the pallet up or replace damaged pallets without having to manually dismantle and reassemble the entire load. It improves efficiency and safety in the warehouse and reduces the risk of injury from manual handling.

Pallet changer

PW 1000

Pallet changer

PW 2000

Pallet changer

PW 3000

Pallet changer

PW 4000

Pallet changer

PW 5000

Pallet changer

PW 6000

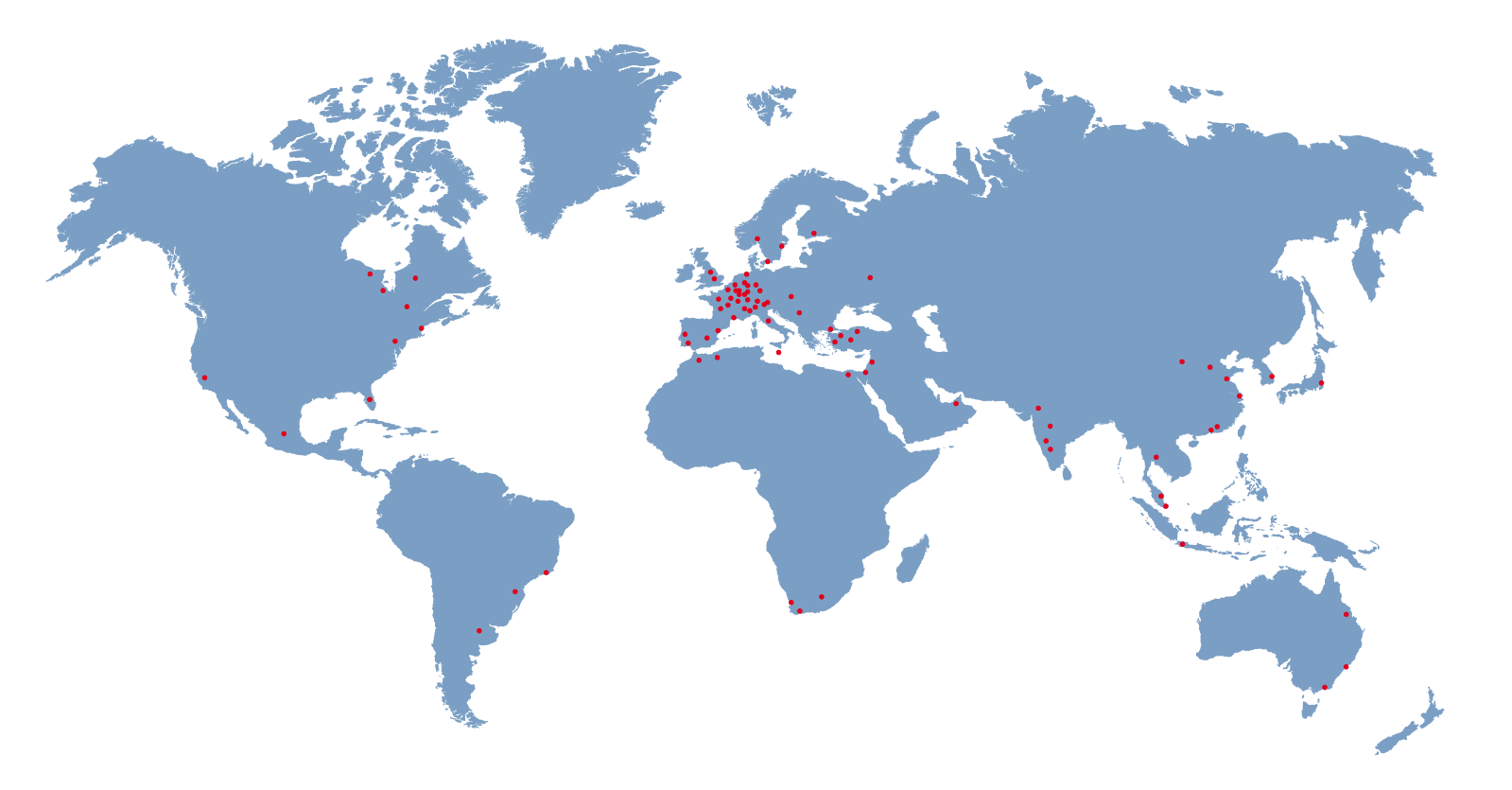

GLOBAL COMPANIES

who trust in Baust pallet changers

Increase Your Warehouse Efficiency with Our Pallet Inverter Machines

Increasing your warehouse efficiency can be seamlessly achieved with our pallet inverter machines, which provide efficient means of inverting loads for various applications. These innovative devices are designed to streamline the pallet exchange quick and simple, ensuring fast and safe transfer of product to pallet during the inversion process.

By implementing a manual pallet inverter or a more advanced stationary pallet inverter with hydraulic systems, you can significantly reduce manual labor and minimize the risk of damaged goods at the bottom of loads. This not only speeds up operations but also improves the overall workflow in your warehouse, especially when handling materials that need to rotate 180 degrees.

Our pallet inverter solutions are versatile handling equipment, catering to various industry needs and applications, making them an essential addition to any logistics setup. Utilizing these machines allows for the easy rotation of heavy loads, whether they’re on a wood pallet or plastic pallet, facilitating better storage management and inventory control.

The pallet inverter cost is quickly offset by the increased productivity and reduced labor expenses. Investing in a pallet rotator ensures that your warehouse operates more efficiently, ultimately boosting your bottom line. For businesses with tight spaces, our portable pallet inverter models offer the same functionality with added flexibility.

Whether you need a compact, inline pallet inverter or a robust build system for heavy-duty tasks, our wide range of options guarantees the perfect material handling solution for your operational needs. We also have several pallet inverter for sale options to fit different budgets.

The Impact of a Pallet Inverter on Your Bottom Line

The impact of a pallet inverter on your bottom line is profound, as it enhances operational efficiency and reduces costs through cost-effective pallet inversion.

Implementing a pallet inverter machine streamlines the process of exchanging pallets, which is crucial for maintaining a smooth workflow in busy warehouses. By automating this task with simple push button operations, you can significantly decrease the time and effort required for manual pallet handling, thus lowering labor costs even when dealing with custom pallet configurations.

Moreover, the pallet inverter price is a worthwhile investment considering the long-term savings and productivity gains. These machines also help in reducing product damage during handling, ensuring that goods remain intact and minimizing losses. Our forklift pallet inverter models further enhance flexibility, allowing you to invert loads easily without relying on extensive manual intervention. This operational efficiency translates into faster turnaround times, enabling you to meet customer demands more effectively and improve overall shipment satisfaction.

Consequently, the use of pallet inverters can lead to higher profitability by optimizing resource allocation and enhancing the quality of service. Inverters provide significant advantages especially when dealing with slip sheet applications or when switching loads between standard pallet types.

By choosing us as a pallet inverter manufacturer, you ensure that your investment yields lasting benefits, ultimately contributing to a stronger financial performance, whether you’re handling wooden pallet loads or industrial pallet configurations.

Transform Your Material Handling with a Forklift Pallet Inverter

Transforming your material handling processes becomes effortless with a forklift pallet inverter that can tilt 180° for complete load inversion.

These innovative machines are designed to facilitate the rotation and exchange of pallets directly using a forklift, making them ideal for dynamic and fast-paced environments. By integrating a rotator into your operations, you can significantly enhance the efficiency and safety of pallet handling. This transformation leads to quicker turnaround times and improved workflow, as the need for manual intervention is greatly reduced.

Our selection of pallet inverter machines includes both stationary and portable pallet models, ensuring that you find the perfect solution to match your specific requirements. Many of our models come with convenient lever controls for precise operation.

Using a forklift pallet inverter also minimizes the risk of injury to workers by reducing the physical strain involved in manually flipping or rotating loads. These machines help maintain product integrity, preventing damage that can occur during traditional handling methods, especially when dealing with the bottom of the load.

The pallet inverter cost is quickly offset by the operational improvements and cost savings achieved through enhanced material handling efficiency. Our equipment solutions include options for pallet replacement when dealing with broken pallets.

By leveraging the capabilities of a hydraulic pallet inverter, you can optimize your logistics and ensure a more streamlined and productive operation for load and transfer tasks.

Seasonal Demands? How a Pallet Inverter Machine Can Help

Addressing seasonal demands efficiently is possible with the help of a pallet inverter machine that can be used for slip sheet or rental pallet transfers. During peak periods, such as holidays or special promotions, the ability to handle increased volumes of goods quickly and accurately is crucial.

A pallet inverter facilitates this by speeding up the process of transferring products between different pallets, thereby enhancing the flexibility and responsiveness of your supply chain. Our inline pallet inverter models with disconnect panel features are particularly effective for continuous operations, ensuring that there is no disruption in the workflow even during high-demand seasons.

Additionally, when looking for a portable pallet inverter for sale, the investment provides significant returns through increased efficiency and reduced labor expenses. Using a stationary pallet inverter can also help in managing excess inventory by allowing for easy reorganization and redistribution of goods. This capability is essential for accommodating fluctuating stock levels and ensuring that your warehouse remains organized and efficient, especially when items need to be loaded and unloaded frequently.

By incorporating a rotator machine into your operations, you can better manage the ebbs and flows of seasonal demand, ensuring that your business continues to operate smoothly and profitably all year round, even when dealing with hygienic requirements for certain industries.

Other advantages of pallet inverters summarized at a glance

- Increased efficiency: a pallet inverter enables more efficient pallet handling by facilitating the turning or flipping of products for proper storage. This can lead to faster processing and therefore higher productivity, especially for rotating loads.

- Easy replacement of defective pallets: With a pallet inverter, damaged pallets can be replaced with a new pallet with ease. This can reduce downtime and increase efficiency.

- Reduction of physical strain: Using a pallet inverter reduces the physical strain of manual labor. This can lead to reduced sick time and increased job satisfaction, particularly when a pallet is manually handled otherwise.

- Flexibility: pallet inverters can be used in a variety of industries – from food and pharmaceuticals to retail stores and warehouses, supporting various applications from slipsheet handling to box dumpers functionality.

- Safety: A pallet inverter with rail guarding can help increase safety in the workplace. It minimizes the risk of accidents that can occur due to improper lifting or moving of heavy pallets.

- Cost savings: By improving efficiency and reducing downtime, a pallet inverter can help reduce operating costs and provide a cost-effective solution for pallet management.

We offer the following types of pallet inverters

Mobile pallet inverter

Mobile pallet inverters are designed to be moved around a warehouse or distribution center. These portable options are equipped with wheels and can be operated by a single person. Mobile pallet inverters are ideal for environments where space is limited or where pallet loads need to be turned at various locations within the facility. Their low profile design makes them perfect for tight spaces.

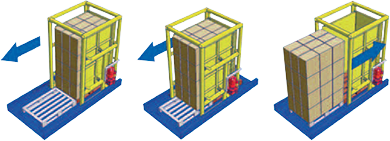

Stationary pallet inverter

Stationary pallet inverters, as the name implies, are fixed in one location. These machines are typically larger and can handle heavier loads than their mobile counterparts. They are often integrated into a production line or used in a specific area for turning or replacing pallets.

Stationary pallet inverters can be equipped with different functions and additional equipment. For example, some models have a clamping device with a short arm boom that holds the load securely during the turning process, while others use a turntable or a combination of both. The opening range and load capacity of stationary pallet inverters can vary depending on the specific model.

Both mobile and stationary pallet inverters help increase efficiency and reduce manual labor in various industries, including food and beverage, pharmaceutical and manufacturing.

Pallet inverter for forklifts from Baust

Many companies today rely on efficient warehouse management to optimize their processes. A pallet inverter for the Baust forklift is a popular tool for turning pallets quickly and safely. This not only saves time, but also money and space. A pallet inverter is usually easy to use and can be attached to almost any forklift truck. It makes it possible to transport and stack pallets safely. With a pallet inverter for the forklift from Baust, even heavy objects can be moved without any problems, making the work easier and faster.