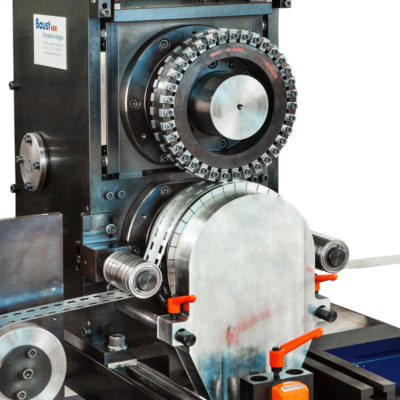

BRV-Series

Punching units for extra fast and precise tool changing

Shorter production runs, less inventory, make-to-order processes – A clear trend in the sheet metal industry which the Baust Stanztechnologie with the BRV series absolutely corresponds. The punching units are available as a coil-driven version or a powerful servo drive variation.

The coil-driven BRV punching unit

In the fully mechanical version, the punch slot BRV is driven by a coil. If the user wants to change the coil, a compressed air cylinder moves the tools so far apart that the punches and dies are out of engagement. This allows the new coil to be easily placed between the tools. A quick change of the punching tools is also possible in this position. Another peculiarity of the coil-driven BRV is the patented turning mechanism. It is arranged in such a way that the tools remain permanently synchronized. The result: the tools can be easily closed pneumatically and continue the punching process directly. At line speed of 60 m/min and more.

Specifications

- Width: approx. 370 mm

- Depth: Approx. 700 mm (approx. 1100 mm with motorized version)

- Height: approx. 560 mm

- Weight: approx. 350 kg

- Production speed: Up to 80 m/min

- Air pressure drive: 6 bar

- motor power (optional): Servo drive 400 V, 50 Hz, max. 3.5 kW or coil driven/fully mechanical

Products to be punched

- Material: steel, aluminium

- Thickness: 0.2 mm – 0.8 mm

- Width: 20 – 100 mm

- Tensile strength: 550 N/mm ²

- Hole spacing: Small enough so that more than one punch is always on

- Tolerance: ISO 2768-1 C

Request a non-binding offer now