Pallet changers

Safe pallet changing in every branch of industry

Baust offers a wide choice of high performance machines in the field of pallet changers. No matter how varied the differing fields of application are, the Baust pallet changers are simple to operate, treat the goods gently and offer the highest safety standards. Whatever the focus, whether it is the adherence to strict hygiene regulations in the pharmaceutical or food industry, or the trouble-free operation in warehouse and logistics management, the Baust pallet changers are used in a wide variety of industries. Choose your Pallet changer and get in contact.

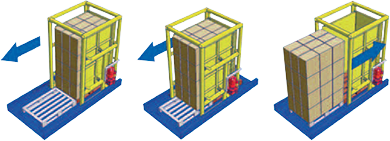

Repalletize processes with pallet changer

Pallet changers with the clamping method

Palletize robust goods quickly and cheaply

- Side clamping of the goods

- Simplest and cheapest option for particularly robust goods

- pallet inverting: Ideal for palletizing cardboard boxes and boxes

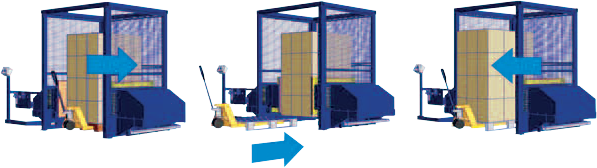

- Lowering and exchanging the pallet using a hand pallet truck or a lifting roller conveyor

- Performance: up to 50 changes per hour

Pallet changer

PW 500

Pallet changer

PW 500 Inline

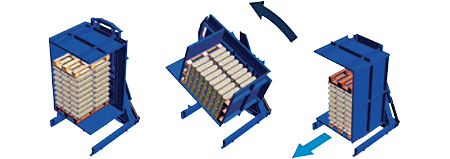

Pallet changers with the inverting and tilting method

Suitable for many pallet sizes

- Rotate or tilt the goods by 90 to 180°

- Ideal for palletizing sacks and big bags

- Overhang of the goods is not a problem

- Reliable even with poor pallet quality and different pallet dimensions

- Performance: up to 55 changes per hour

Pallet inverter

PW 600

Pallet inverter

PW 600 Inline

Pallet inverter

PW 700

Pallet changer

PW 800 E

Pallet changer

PW 800 C

Pallet changer

PW 800

Pallet changer

PW 800 Inline

Pallet changer

PW 900 Inline

Pallet changer

PW 1000

Pallet changer

PW 2000

Pallet changer

PW 3000

Pallet changer

PW 4000

Pallet changer

PW 5000

Pallet changer

PW 6000

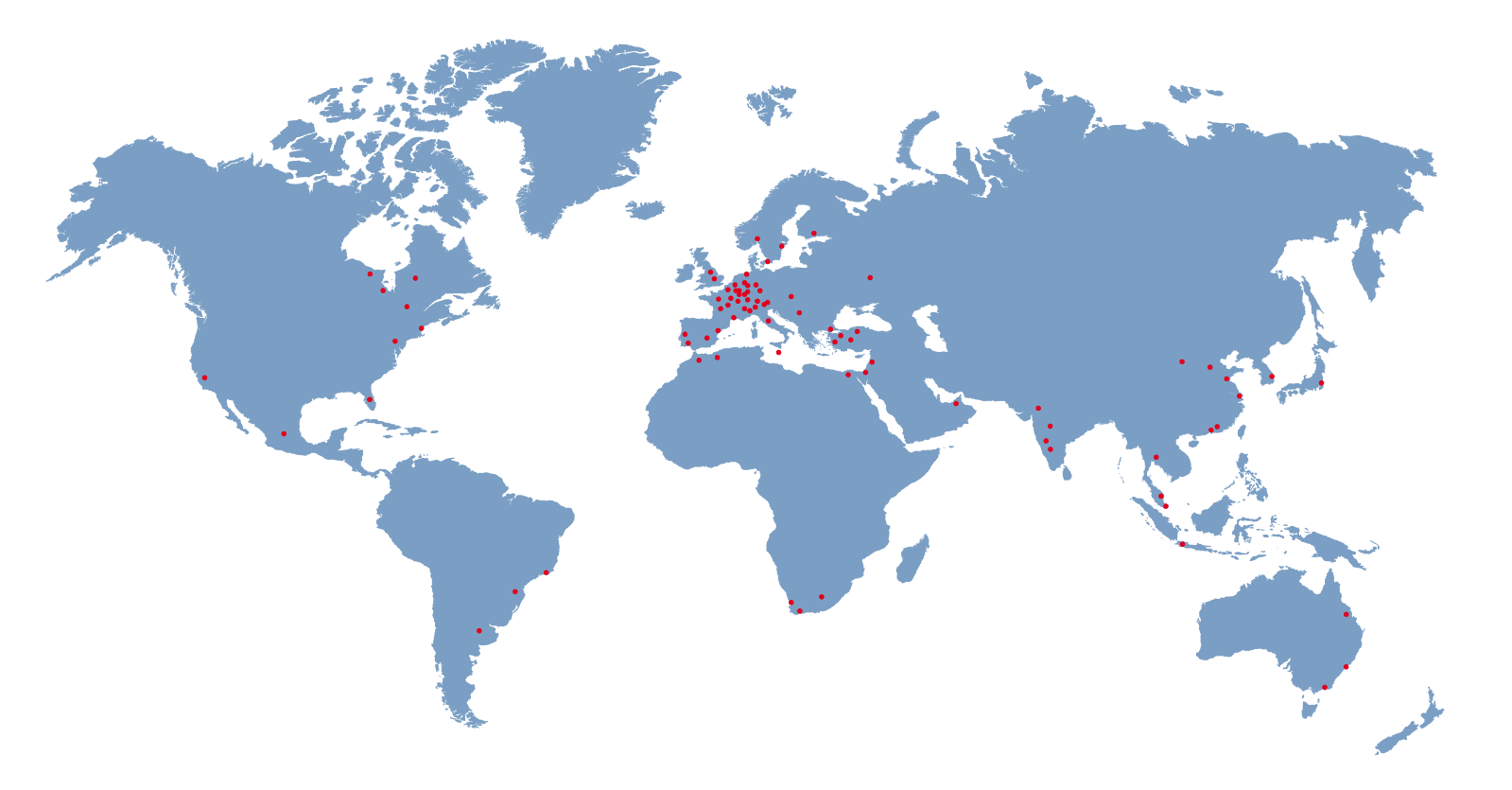

GLOBAL COMPANIES

who trust in Baust pallet changers

Future-Proof Your Operations with a High-Quality Pallet Changer

Investing in a high-quality pallet changer is a strategic move to future-proof your operations. An automatic pallet changer can unlock hidden productivity in your manufacturing process while reducing the time when your spindle isn’t cutting.

As industries evolve and demands for efficiency and productivity increase, having a reliable pallet changer machine becomes essential. These machines are designed to handle various types of loads, ensuring smooth pallet transfer between different pallets without interrupting your workflow. With an auto pallet changer, you can achieve serious productivity gains while minimizing downtime.

A stationary pallet changer can be an excellent addition to your machine center, providing consistent and reliable performance. It helps reduce manual labor and minimizes the risk of damage to goods, thus helping boost efficiency across your operations. Many businesses find that after implementing a manual pallet changer, they can later upgrade to automatic pallet changers for even greater benefits.

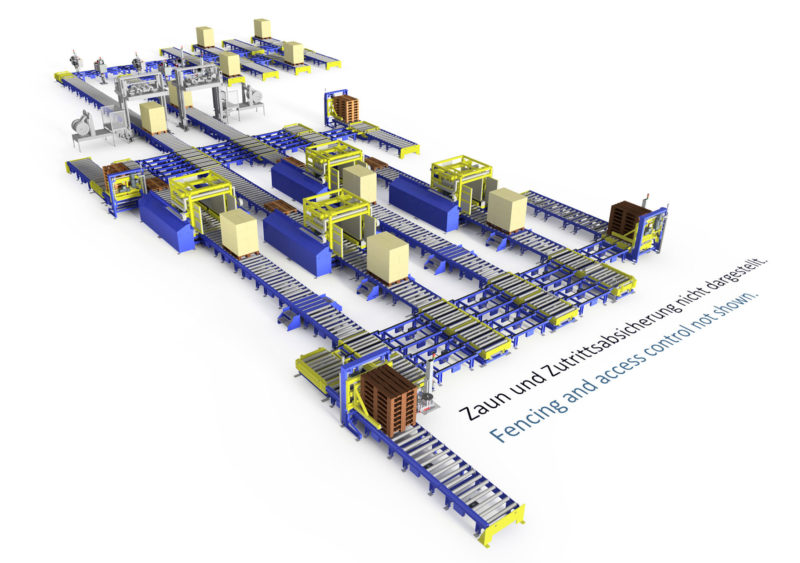

Additionally, a robust pallet changer system offers flexibility and adaptability, allowing your operations to scale efficiently as your business grows. By incorporating this technology, you are not only improving current processes but also preparing your facility to meet future challenges and opportunities. The integration of advanced inline pallet changers ensures that your production line remains uninterrupted, offering seamless and automated pallet handling for both plastic pallets and wooden pallets.

This forward-thinking approach is crucial for staying competitive in an ever-changing market, making a pallet changer solution an investment that pays off both now and in the long term. As a leading manufacturer of pallet changer systems, we understand how the right equipment solutions can transform your productivity.

Revolutionize Your Logistics with Our Pallet Changer Machines

Our pallet changer machines are designed to revolutionize your logistics by streamlining pallet handling processes. Efficient logistics are vital for any business, and the implementation of an automatic pallet changer can significantly improve your material handling operations. With the right hydraulic mechanisms, our auto pallet changer system can process multiple pallets per hour.

These machines are versatile and can handle various types of pallets, including hygienic pallets for specialized industries, making them suitable for different applications. Whether you require a stationary pallet changer for a fixed location or a mobile pallet changer for flexible operations, our changer models cater to your specific needs. Our storage system integrates perfectly with your existing pallet infrastructure.

By automating the pallet changing process, you reduce the need for manual intervention, which in turn minimizes errors and speeds up the workflow. This automation leads to a more efficient supply chain, where goods are moved quickly and accurately from one stage to another. The use of our pallet technology can help lower costs significantly over time.

Additionally, using an automatic pallet changer enhances safety in the workplace by reducing the physical strain on workers and lowering the risk of accidents when they load and unload materials. Our diverse range of pallet changer systems ensures that you find the perfect fit for your logistics requirements, helping you achieve greater efficiency and reliability in your operations. A conveyor-integrated system can further optimize your material flow.

Why a Pallet Changer is Essential for Modern Warehousing

In modern warehousing, the use of a pallet changer is essential for optimizing storage and handling operations. Warehouses today face the challenge of managing large volumes of goods while maintaining accuracy and efficiency. A manual pallet option might work for smaller operations, but most businesses benefit from automatic solutions.

A pallet changer machine simplifies this task by automating the process of transferring goods between different pallets. This automation is crucial for reducing labor costs and minimizing the risk of product damage, leading to more efficient storage management. With proper workholding solutions, even delicate items can be safely transferred.

A stationary pallet changer can be strategically placed within your warehouse to facilitate quick and easy change pallet operations, ensuring that your inventory moves smoothly through various stages of processing. For operations requiring material movement across larger areas, a mobile solution can be ideal. When integrated with a pallet pool system, you can further reduce costs and streamline operations.

Using a pallet system not only increases operational efficiency but also enhances the overall organization and management of your warehouse. With these benefits, an automatic pallet becomes an indispensable tool in modern warehousing, enabling you to meet the demands of a fast-paced industry effectively. When your machine tool requires consistent material feeding, our transfer machine capabilities ensure continuous operation.

Our Pallet Changer Systems Support Sustainable Practices

Our pallet changer systems are designed to support sustainable practices within your operations. Sustainability is becoming increasingly important across all industries and investing in an automatic pallet changer can play a significant role in achieving your environmental goals.

These machines help reduce waste by optimizing pallet usage and minimizing damage to goods during handling. A forklift might damage pallets during traditional handling, but our systems ensure gentle transitions. Our selection of automatic pallet changers ensures that there’s a perfect solution for every application, whether you need to handle standard wooden pallets or specialized materials.

Using an inline pallet changer further enhances sustainability by automating repetitive tasks, thereby reducing energy consumption and improving overall operational efficiency. When properly integrated with your existing pallet architecture, our automated systems can substantially reduce your carbon footprint while boosting productivity.

By choosing our solutions, you are not only improving your operational efficiency but also contributing to a greener environment. A forklift-compatible design ensures easy integration with your current material handling equipment. This commitment to sustainability is essential for building a responsible and forward-thinking business, making the auto option a valuable asset in your pursuit of eco-friendly practices that simultaneously deliver serious productivity gains through reduced downtime.