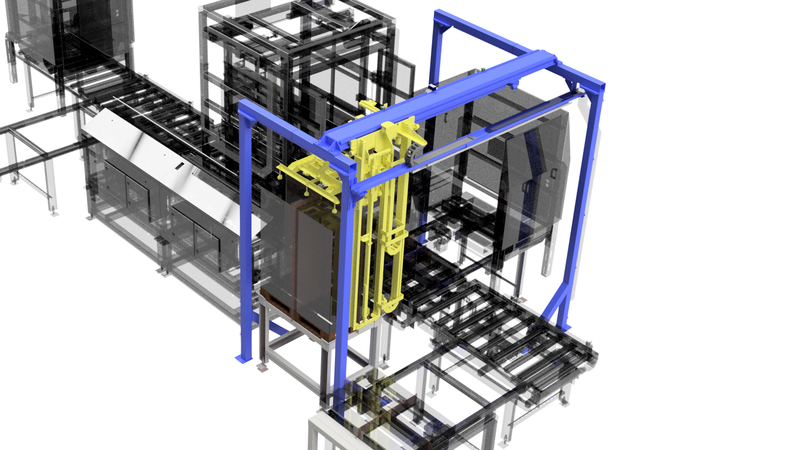

Slip sheet dispenser

Fully automated dispensing and collecting of slip sheets

The slip sheet dispenser is the perfect addition to any automatic palletizing system. A slip sheet between the load and the pallet is particularly recommended for sensitive goods and decreasing wooden pallet quality.

- functions: Automatically dispense or collect coversheets

- loading by forklift or integrated conveyor

- position before, within or after the pallet changing process

Specifications

- performance: 40 – 60 cycles/h

- dimensions (L x W x H in mm): 2700 x 1800 x 2900 – 3600

- lifting & traversing axis: electrically driven

- slip sheet fixing: pneumatically driven

- loading & unloading: forklift/conveyor technology

- control mode: automati

- power supply: 4 kVA – 16A 400 V R1/2″, 6 bar

Pallet & slip sheet data

- stacking height incl. pallet: 1500 mm

- material: cardboard or plastic

- weight: min. 267 g/cm2, min. 3 mm thickness

- standard dimensions (W x L in mm): 800 – 1000 x 1200

- max. passage height: 2000 mm (goods incl. pallet)

Options

- different slip sheet sizes

- other stacks and passage heights

- supply of several positions

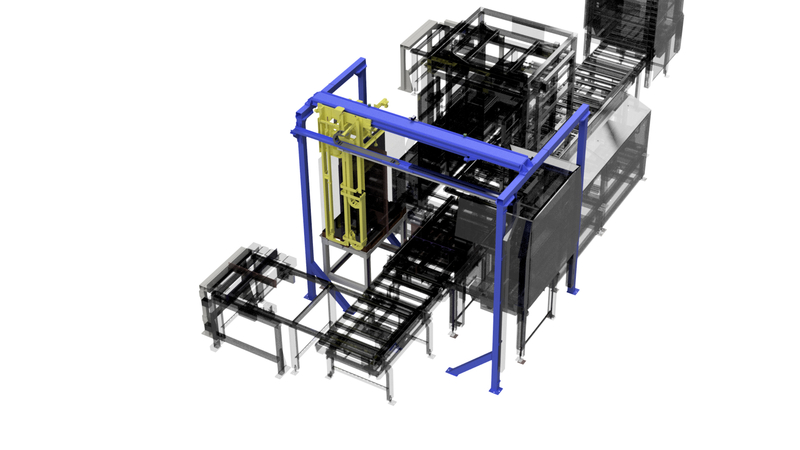

Integrated slip sheet handling in practice

Dispensing: If the finished product is palletized from a hygiene pallet made of plastic or aluminium onto a wooden pallet after production in the outgoing goods department, it makes sense to use a protective slip sheet. The additional protection between the goods and the pallet can also be used to secure the positon of load with an appropriate anti-slip coating. The slip sheet is individually removed from the stack by suction pressure and placed on the respective pallet.

Collecting: At goods receiption, the system changes from the external pallet to the internal pallet for various reasons. To use the empty pallets for further processing or transfer, it may make sense to remove the old cover sheets using a slip sheet dispenser.

In both cases, the position of the loading station is decisive for the cycle and the space requirement of the entire system: Depending on the individual project requirements, the slip sheet dispenser can be positioned in front of or behind the pallet changer. In addition, it is also possible to integrate both machines into one another.

We recommend the slip sheet dispenser for 40 to 60 cycles per hour.

Request a non-binding offer now

Boost Your Warehouse Efficiency with our Slip Sheet Dispenser

In the fast-paced world of logistics and warehousing, efficiency is key to staying competitive. Our slip sheet dispenser is designed to revolutionize your material handling processes, offering a streamlined solution that significantly boosts warehouse productivity and transforms your operation across the entire industry.

By automating the process of inserting slip sheets between layers of goods on pallets, our automatic system eliminates the need for manual labor in this repetitive task. The construction of our automatic slip sheet dispenser allows it to safely handle and dispense sheets with precision. This not only speeds up the palletizing process but also reduces the risk of human error and potential injuries associated with repetitive motions. The precision of our slip sheet dispenser ensures that each sheet is placed accurately in the correct position, creating stable and uniform pallet loads that are easier to transport and store.

Moreover, the increased speed of operations allows for a higher throughput, enabling you to process more orders in less time. The user-friendly interface of our sheet dispenser makes it easy for your staff to operate, requiring minimal training and allowing for quick integration into your existing workflow and conveyor systems. The system can deliver consistent results and collect valuable operational data.

With adjustable settings to accommodate various pallet sizes and load types, our slip sheet dispenser offers the specification flexibility needed to handle diverse product lines efficiently. The machine can seamlessly integrate with your current equipment setup and station configuration, providing comprehensive handling solutions for your facility.

Why Your Company Needs a Pallet Slip Sheet Dispenser

In today’s competitive business landscape, staying ahead requires continuous improvement in operational efficiency. A pallet slip sheet dispenser is not just an addition to your warehouse equipment; it’s a strategic investment in your company’s future and a comprehensive solution for modern handling challenges in any industrial environment.

By automating the slip sheet insertion process, you’re addressing several critical aspects of your operations simultaneously. The system excels at handling slip sheets with precision, utilizing a slip-sheet dispensing mechanism that can withstand heavy-duty operations. Firstly, it significantly reduces labor costs associated with manual sheet placement, allowing you to allocate your workforce to more value-added tasks. Secondly, it enhances workplace safety by eliminating the need for repetitive bending and lifting, thus reducing the risk of musculoskeletal injuries among your employees.

The consistency provided by our pallet slip sheet dispenser also improves load stability, minimizing product damage during transportation and storage. This leads to fewer returns and higher customer satisfaction. Furthermore, the increased speed and efficiency in your palletizing process allow for better inventory management and faster order fulfillment, giving you a competitive edge in the market.

The adaptability of our system to various product types and different size requirements means you can handle a wide variety of goods without compromising on efficiency or quality. The dispenser can efficiently stack materials and transfer loads from empty pallet to empty pallet with precision, ensuring each palletized load is secure and stable.

Cut Costs and Increase Productivity with Our Pallet Slip Sheet Dispenser

Investing in our pallet slip sheet dispenser is a strategic move that yields both immediate and long-term financial benefits for your company. By automating the slip sheet insertion process through advanced automation, you’ll see a significant reduction in labor costs associated with manual palletizing. This innovative tool not only cuts direct expenses but also minimizes the indirect costs related to employee turnover and training in this labor-intensive role.

The increased speed and efficiency of our system allow for a higher volume of goods to be processed in less time, effectively boosting your overall productivity. This enhanced throughput can lead to improved order fulfillment rates and potentially increased sales capacity. Additionally, the precision of our pallet slip sheet dispenser reduces material waste by ensuring optimal use of slip sheets and minimizing damage to goods during the palletization process.

The improved stability of pallet loads also translates to reduced product damage during transportation and storage, further cutting costs associated with returns and replacements. Moreover, the energy efficiency of our sheet dispenser contributes to lower operational costs over time. The robust construction features an anti-slip coating and rail system that ensures reliable performance.

The scalability of our solution means it can grow with your business, providing long-term value and eliminating the need for frequent equipment upgrades. The machine offers multiple option configurations and can be customized to meet your standard requirements. Our sheet handling technology delivers superior handling solutions that can efficiently dispense materials as needed.

From Manual to Automated – The Pallet Slip Sheet Dispenser Advantage

The transition from manual to automated palletizing represents a significant leap forward in warehouse operations, and our pallet slip sheet dispenser is at the forefront of this evolution across the industry. Manual insertion of slip sheets is not only time-consuming but also prone to inconsistencies and errors. Our automatic system eliminates these issues, ensuring precise and uniform placement of slip sheets every time, including the critical slip sheet on top of each load.

This consistency is crucial for maintaining load stability and preventing product damage during transportation and storage. The automation also allows for continuous operation, without the need for breaks or shift changes, leading to uninterrupted productivity. Our pallet slip sheet dispenser can be seamlessly integrated into existing conveyor systems or work as a standalone unit, offering flexibility in warehouse layout and design. The system’s advanced sensors and control mechanisms adapt to various product sizes and weights, ensuring optimal performance across different product lines. The mechanism actuates to the pick point with precision timing.

This versatility is particularly valuable for businesses with diverse product portfolios. The dispenser features a reliable magazine system that holds multiple sheets and automatically feeds them as needed. The machine can efficiently place each sheet and handle the transfer of materials between different pallet configurations through advanced slip sheet dispensing technology.

Furthermore, the data collection and analysis capabilities of our automated system provide valuable insights into your palletizing operations, allowing for continuous process improvement and optimization. The reduced physical strain on workers not only improves safety but also contributes to higher job satisfaction and retention rates among warehouse staff. The conveyor integration capabilities ensure smooth material flow throughout your facility.

Pallet Slip Sheet Dispenser – The Game-Changer in Modern Logistics

In the ever-evolving landscape of logistics and supply chain management, our pallet slip sheet dispenser stands out as a true game-changer. This innovative solution addresses multiple challenges faced by modern warehouses and distribution centers. By automating the slip sheet insertion process, it significantly reduces the time required for palletizing, allowing for faster turnaround times and improved order fulfillment rates. This speed is crucial in meeting the growing demands of e-commerce and just-in-time inventory systems.

Our pallet slip sheet dispenser also plays a vital role in optimizing space utilization within warehouses. The precise placement of slip sheets allows for more stable and compact pallet loads, enabling higher stacking and more efficient use of vertical space. This can lead to increased storage capacity without the need for physical expansion. The system’s ability to handle various types of slip sheets, including plastic, paper, and corrugated materials, provides flexibility in packaging options and can contribute to sustainability efforts by facilitating the use of eco-friendly materials.

The dispenser can efficiently stack materials in various configurations and seamlessly place each sheet where needed. The automatic system can handle both empty and loaded pallets with equal precision, making it versatile equipment for any handling operation. The drive system ensures reliable performance and consistent sheet placement.

Furthermore, the advanced control systems of our sheet dispenser allow for seamless integration with warehouse management systems (WMS), enabling real-time tracking and optimization of the palletizing process. This level of integration and data visibility is essential for modern logistics operations, providing managers with the insights needed to make informed decisions and continually improve efficiency. The conveyor compatibility ensures smooth integration into existing material handling workflows, while the flexibility to automate various processes makes this machine an invaluable addition to any facility seeking to enhance their handling capabilities.