Centering station & all-side centering device for goods

Optimum logistics management thanks to centering station from Baust

Efficient material flow systems are an important area of logistics management. Through the use of high-quality machines, it is possible to transport goods elements to the desired destination inside a company and in addition improve the safety and efficiency of the packaged goods on the pallets. All side centering stations from Baust play a decisive role here. Even you can secure the benefits of our products and improve your logistics and warehouse management.

- gentle positioning of packaged goods and pallets

- better pallet safety and packing quality

- reduced packing costs

- economical handling

- easier, automatic depalletising

- safe transport

Specifications

- performance: 30 – 100 cycles/h

- control mode: hold-to-run or automatic control

- loading and unloading: electrical or forklift truck/conveyor technology

- clamping walls: driven by electric or pneumatic

- power supply: 4 kVA – 16A 230/400 V R1/2″, 6 bar

- dimensions (L x W x H in mm): 3350 x 2990 x 3300 to 5500 x 4330 x 3500

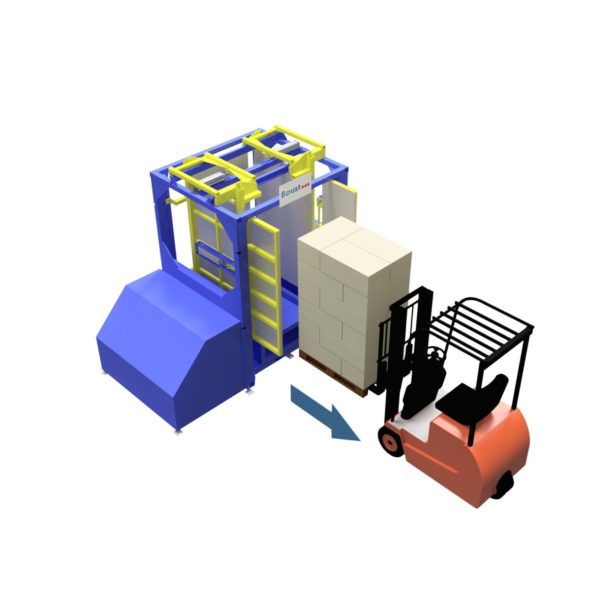

Pallet loading

- total weight up to 1000 kg

- standard pallet (W x L in mm): 800 – 1000 x 1200

- max. Height incl. Pallet: 2000 mm

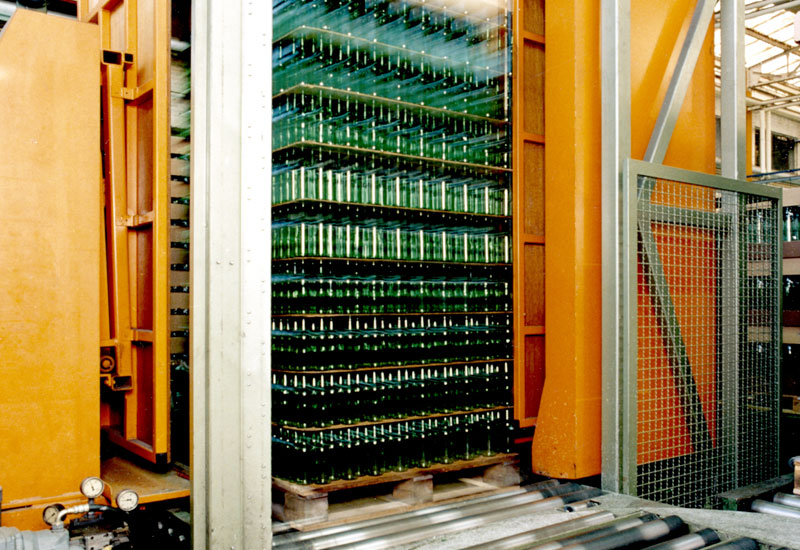

- goods: e.g. cardboard boxes, boxes, big-bags, bottles or pallet stacks

- overhang tolerance for each side: +- 50 mm

Options

- further pallet widths

- pallet height > 2000 mm

- load > 1000 kg

further details on the respective product page (see below)

The all enclosing centering solution for every application

Wherever pallets are moved manually and automatically, malfunctions and stoppages with inclined pallet stacks or slipped loads can occur: A typical location is in the high-bay warehouse pre-zone prior to contour control. In the case of a production line, it may be necessary to precisely align the loaded pallets after the truck transport for further automated processing. The application possibilities are just as varied as the technical challenges that Baust engineers are happy to face.

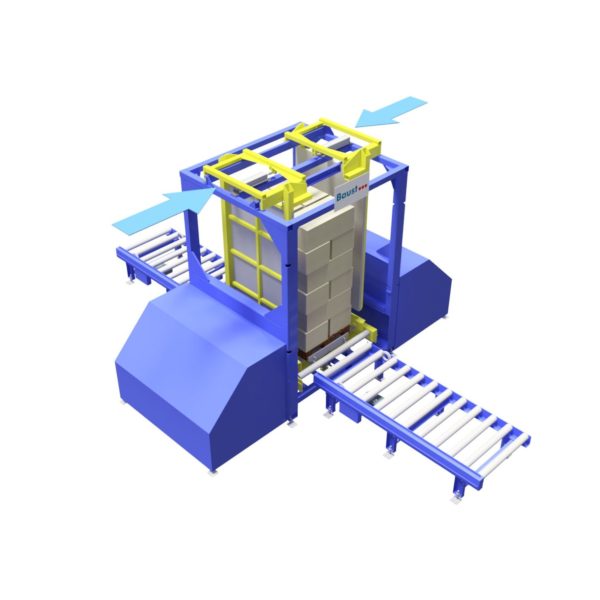

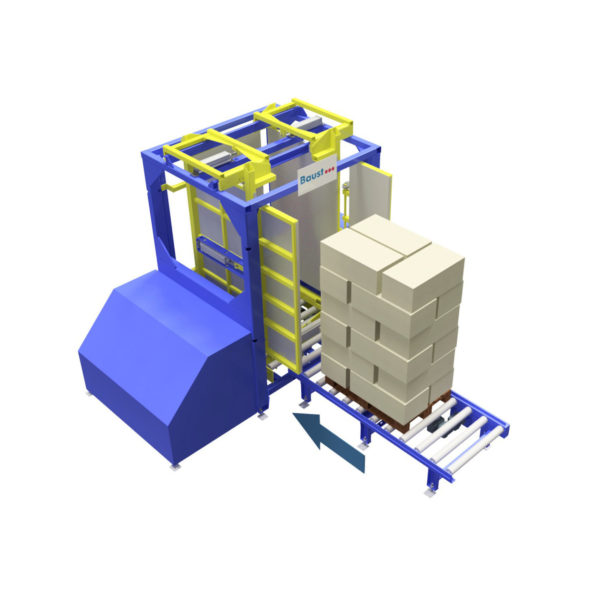

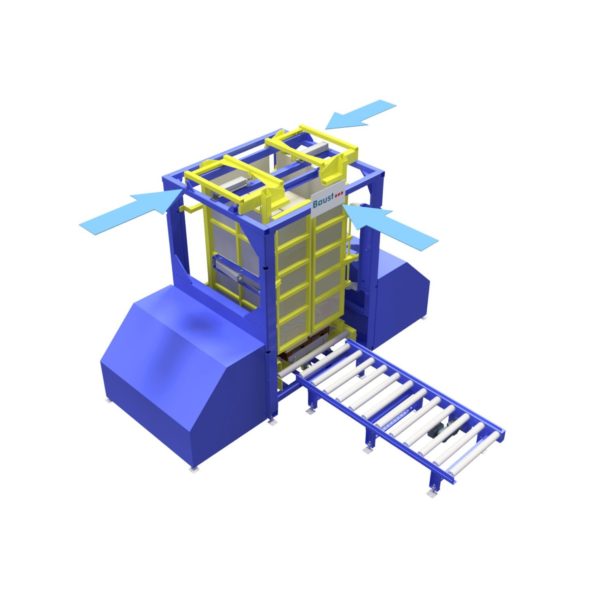

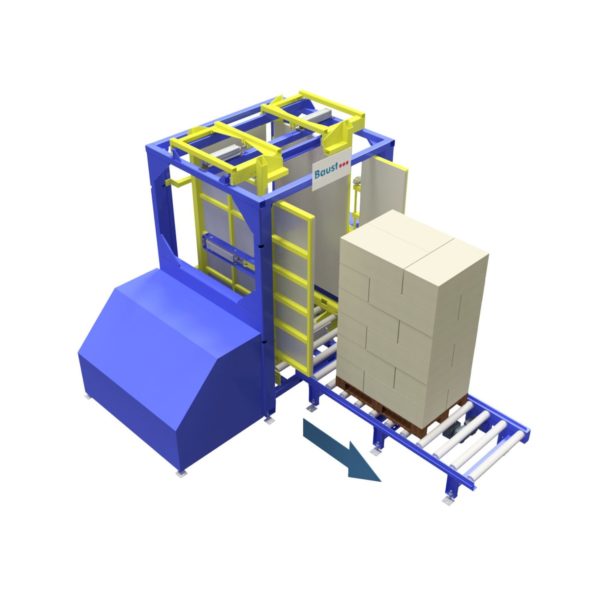

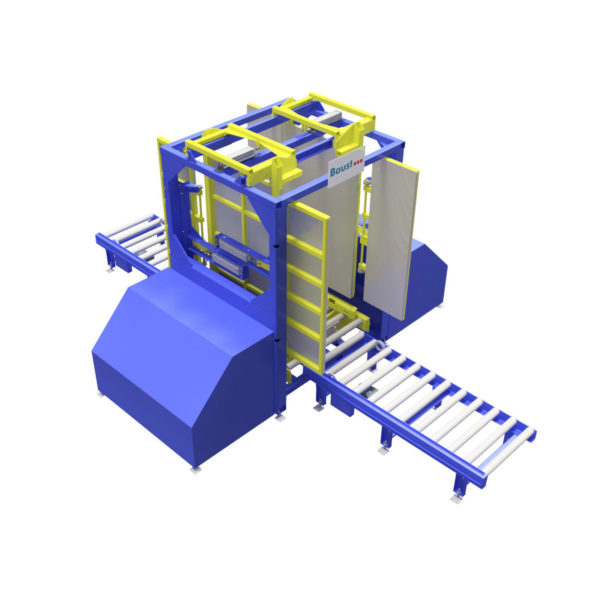

Process flow: The centering device first centers the lowest pallet on the conveyor system and then gently aligns the goods from all 4 sides. Up to 100 centering cycles per hour are possible due to an innovative process sequence and a one-sided material flow according to the travel through layout.

The Baust centering stations

All-side centering for load centering

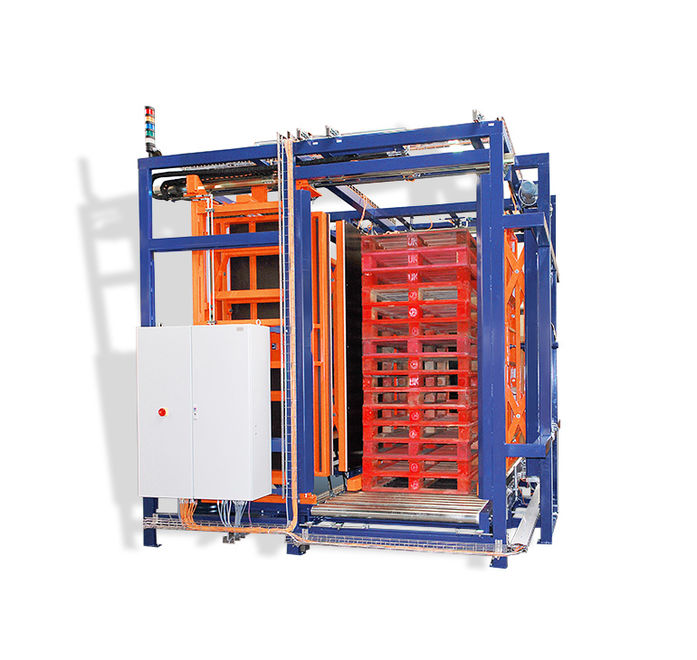

Centering station AZ 1000

The centering system Stand-Alone

The basic model aligns the load safely and efficiently from three sides and, thanks to its dead-end layout, is ideal for niche locations.

- Output: 30 – 50 cycles / h

- Operating mode: dead man’s control

- Loading and unloading: electric pallet trucks or forklifts

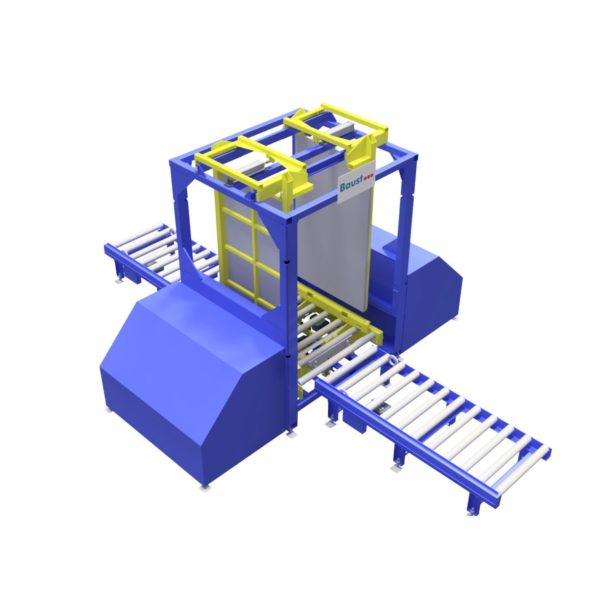

Centering station AZ 2000

The two-sided inline centering

The model aligns the load safely and efficiently from two sides and is ideal for integration into the conveyor line and ensures high throughput rates.

- Performance: 90 – 100 cycles / h

- Operating mode: automatic control

- Loading and unloading: forklifts or conveyor technology

AZ 3000 centering station

The Inline niche centering solution

The model aligns the load safely and efficiently from three sides and, thanks to its dead-end layout, is ideal as an inline system for niche locations.

- Output: 30 – 50 cycles / h

- Operating mode: automatic control

- Loading & unloading: forklifts or conveyor technology

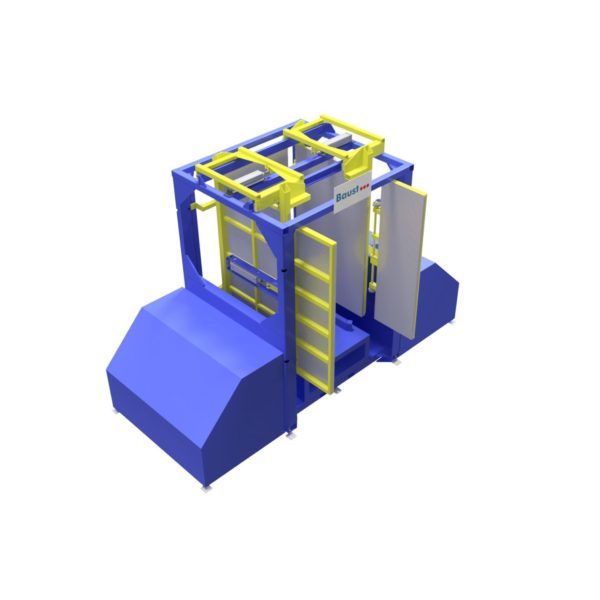

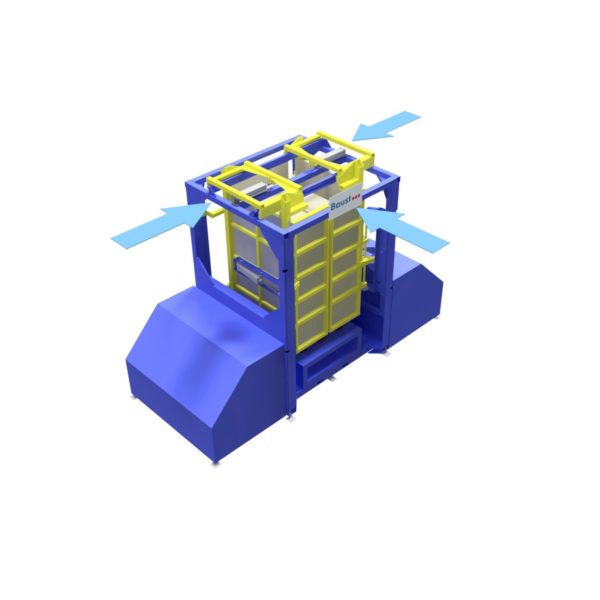

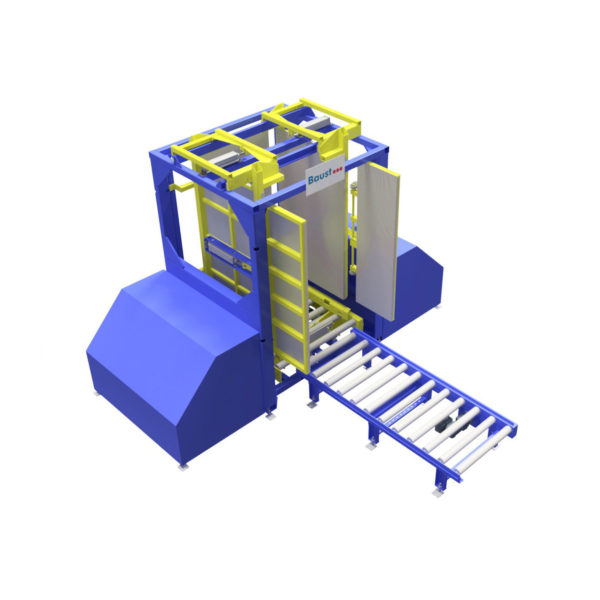

AZ 4000 centering station

High-performance centering from 4 sides

This model aligns the load fully automatically and safely from all four sides. The integration into the conveyor line ensures high throughput rates.

- Performance: 90 – 100 cycles / h

- Operating mode: automatic control

- Loading & unloading: forklifts or conveyor technology

Free initial consultation & technical planning

- Kostenfreie Planung der definierten Spezifikationen

- Free planning of the defined specifications

- Fast, clean and binding development

- Non-binding offer and detailed documentation

- Technical expertise right from the start

- Consulting, planning, production, assembly and maintenance from a single source without subcontractors

Request a non-binding offer now

Centring station for optimum product centring in logistics

Modern logistics processes require precise alignment of packaged goods and pallets. A professional centring station ensures the exact positioning of different types of goods, thereby optimising the entire material flow. Central alignment minimises transport damage and significantly improves stackability.

The implementation of a centring station significantly reduces manual corrections and speeds up automated processes. Employees can concentrate on value-adding activities while the machine reliably ensures consistent goods alignment. The added value of this technology is particularly evident when dealing with different package shapes.

Companies benefit from reduced operating costs and increased throughput. Precise centring also improves compatibility with downstream automation systems and creates consistent quality standards throughout the entire logistics process.

High-quality centring station for logistics management

Efficient logistics management is based on the seamless integration of different system components. A high-quality centring station forms the heart of modern intralogistics solutions and enables smooth goods handling. The robust design ensures continuous operation even under demanding conditions.

Different types of packaged goods require different alignment strategies. Modern centring stations adapt flexibly to changing requirements and process both light and heavy goods reliably. Intuitive operation reduces training times and minimises operating errors.

Long-term operational reliability and low maintenance costs are the hallmarks of high-quality equipment. Companies are therefore investing in sustainable solutions that deliver consistent performance over many years and are characterised by high availability.

Centring station from the manufacturer for better pallet securing

Direct purchase from the manufacturer guarantees authentic quality and comprehensive support. A centring station from the manufacturer offers tailor-made solutions for specific application requirements and ensures optimum compatibility with existing systems. Expert advice supports you in selecting the right configuration.

Pallet securing achieves new dimensions of quality through precise centring. Evenly aligned packaged goods reduce slippage during transport and minimise the risk of damage. Improved stability allows for higher stacking heights and optimises storage capacity.

Manufacturer’s warranty and spare parts supply ensure long-term operational reliability.

Direct communication channels shorten service times and ensure rapid problem resolution. These advantages justify investing in original equipment over alternative products.

Transport routes secured by reliable all-round centring devices

All-round centring devices revolutionise goods alignment through multi-directional centring. This advanced technology detects packaged goods from all sides and positions them optimally for subsequent process steps. Asymmetrical or irregularly shaped goods benefit particularly from this comprehensive alignment method.

Transport risks are significantly minimised thanks to even weight distribution and stable positioning. All-round centring devices guarantee consistent results regardless of the nature or size of the packaged goods. Automatic adjustment to different types of goods eliminates the need for manual readjustments.

Operational reliability and process stability are significantly increased through the use of reliable all-round centring devices. Unplanned downtimes are reduced, while throughput remains consistently high. This reliability forms the foundation of efficient logistics operations.

Optimise packaging quality with a modern centring station

Packaging quality is a key factor in customer satisfaction and transport costs.

A modern centring station creates the conditions for professional goods handling and reduces quality-related complaints. Precisely aligned packaged goods make downstream packaging processes much easier. Companies achieve cost reductions through optimised material utilisation and reduced packaging costs. Evenly positioned goods require less filling material and enable more compact packaging units.

This increase in efficiency has a direct impact on operating costs.

The degree of automation and process speed benefit from consistent product alignment. Modern centring stations integrate seamlessly into existing production lines and support the digitalisation of logistics processes. They thus create the basis for future-proof intralogistics concepts.