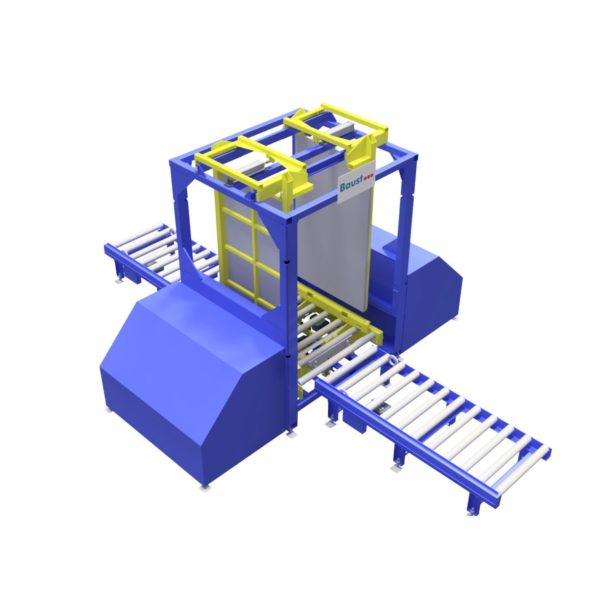

Centering station AZ 2000

The two side Inline centering

The centering station AZ 2000 aligns the load safely and efficiently from two sides. The integration into conveying line ensures high throughput rates.

Specifications

- performance: 90 – 100 cycles/h

- control mode: automatic control

- loading and unloading: forklift/conveying line

- clamping walls: electrically driven

- power supply: 4 kVA – 16A 230/400 V

- dimensions (L x W x H in mm): 5500 x 4330 x 3500

Pallet loading

- total weight up to 1000 kg

- standard pallet (W x L in mm): 800 x 1200

- height incl. pallet: 2000 mm

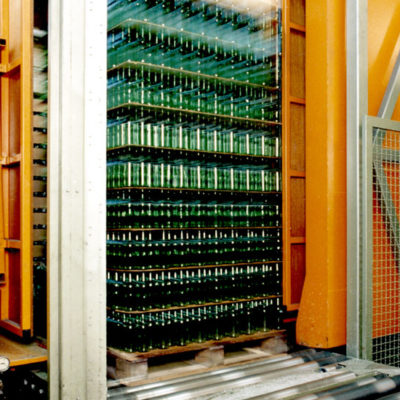

- goods: e.g. cardboard boxes, boxes, Big-Bags, bottles or pallet stacks

- overhang tolerance for each side: +- 50 mm

Options

- other pallet widths

- height of goods > 2000 mm

- load > 1000 kg

The two side Inline centering

The centering station AZ 2000 aligns the load safely and efficiently from two sides. The integration into conveying line ensures high throughput rates.

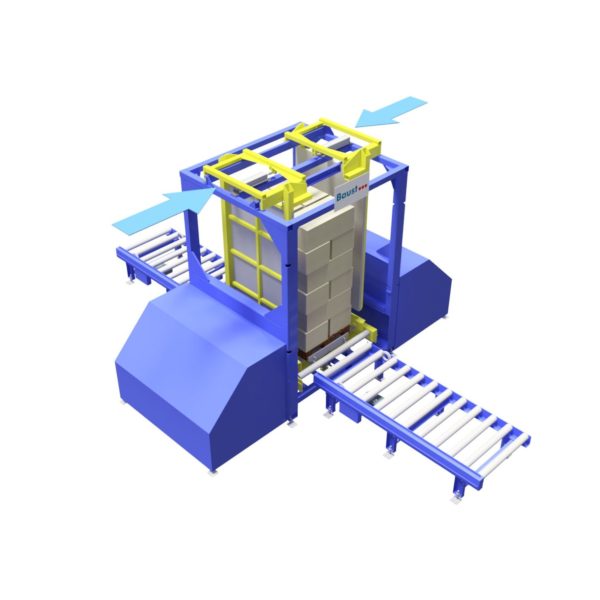

Centering of loads stacked on pallets or complete stacks of empty pallets is always necessary if irregularities in the layer pattern or packing scheme have occurred during palletizing or transport. A low tolerance for stacking and outer contours is an important prerequisite for a safe and trouble-free process, especially in automated further processing and storage. If only the lateral alignment is to be corrected, the centering station AZ 2000 is used. The pallet moves into the machine and is positioned. The two side walls close and press the load together from two sides. The pallet is conveyed through the machine, while the next pallet is driven in at the front.

In this way, up to 100 cycles in one hour are possible. A safety fence with access control ensures the required safety.

Request a non-binding offer now