Hybrid pallet changer | intralogistics

Change pallets, invert pallets, re-palletize and then? That is exactly what we asked ourselves and developed hybrid pallet changers. These pallet changers can combine several processes (clamping, turning / tilting & pushing) or perform other key functions in addition to palletizing.

Beneftis of Hybrid pallet changers:

- Increased utility: Multiple processes or functions integrated in one machine

- Space-saving solution: In intralogistics, minimal floor space is combined with maximum performance

- Reduction of investment costs: One system combines all tasks instead of many individual machines

The possibilities of the different hybrid combinations are almost limitless thanks to our innovative engineers in the mechanical and electrical development department.

Possible Hybrid combinations for pallet changers:

| Hybrid functions: | PW clamping | PW inverting | PW tilting | PW pushing | PW pulling |

| PW clamping | – | – | ✔ | ✔ | – |

| PW inverting | – | – | ✔ | – | – |

| PW tilting | ✔ | ✔ | – | – | – |

| PW pushing | ✔ | – | – | – | – |

| PW pulling | – | – | – | ✔ | – |

| Hygiene lock with zone separation | – | – | – | ✔ | ✔ |

| Centering the load and pallet | ✔ | – | ✔ | ✔ | ✔ |

| Align the load | ✔ | – | ✔ | ✔ | ✔ |

| Slip sheet handling | ✔ | ✔ | ✔ | ✔ | ✔ |

| Double (= stack 2 loads with pallet on top of each other) | ✔ | – | – | – | – |

| Saddle up (= place empty pallet under pallet with load) | ✔ | – | – | – | – |

| Split pallets: e.g. 2x DüDo Pal. | ✔ | ✔ | ✔ | ✔ | ✔ |

| Replace damaged loads | – | ✔ | – | – | – |

| Suction & cleaning | ✔ | ✔ | ✔ | ✔ | ✔ |

Your hybrid solution is not included?

Case study hybrid pallet changer PW 1000 H

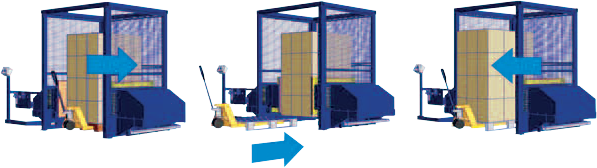

The combination of pushing and pulling process creates the PW 1000 H as a hybrid innovation.

Application:

- The basic pushing method of the PW 1000 cannot always cover all loads and pallet types. So-called push-pull attachments for forklift trucks are known for palletless storage and loading. The engineers at Baust have developed an attachment similar in function.

- Thanks to this special device, the PW 1000 H pallet changer can be also used in pulling mode. A cover sheet or slipsheet between load and pallet is pulled on a protruding flap. The load is pulled from one pallet to the other even more gently than with pushing method. There is no friction between the goods and the pallet.

- The pulling method is ideal for all sensitive and unstable loads that cannot be clamped, inverted, tilted or pushed. These are e.g. yoghurt pots and other dairy products in pots, eggs in carton layers, fruit & vegetables in open cartons.

- The pulling device of the PW 1000 H is closed and opened manually in an ergonomic way: A lot of function and engineering in a small format. Further automations in the models PW 2000 to PW 6000 are also available.

Case study hybrid pallet changer PW 2000 H

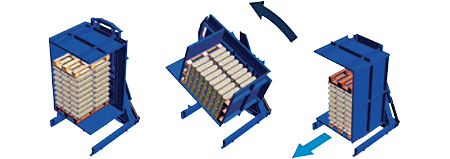

The gentle sliding process is supplemented by the powerful clamping process.

Application:

- Pallets and loads are often diverse so that several PW processes are required.

- Pushing is particularly suitable for the re-palletizing of sensitive loads, which must not be tipped or clamped. Gaps in the stack are not a problem. Source pallets (= pallets that carry the load before changing) with edges or outstanding structures are critical.

- A smooth surface of the source pallets is not necessary when clamping. As a result, pressure-stable and robust loading can alternatively be changed to another pallet using the clamping function of the PW 2000 H.

- The advantages of the sliding process are combined with those of clamping.

Case study centering PW 3000

The position of the goods on the pallet can be adjusted both lengthways and crossways during pushing. In addition to changing pallets in lock operation, centering is also significantly improved.

Case study slip sheet handling

- The cover sheet or slip sheet, as an important separating layer, protects the bottomside of the load from dirt or damage from the pallet.

- But what happens to this frequently used slip sheet during the pallet change? Quite simply: it can remain on the source pallet or remain fixed on the goods. In the worst case, it can disturb the process.

- To prevent this, various slip sheet options can be integrated in the pallet changer to increase process reliability.

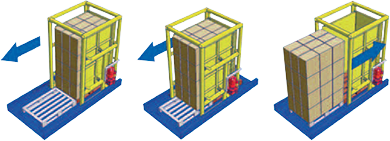

Case study hybrid pallet changer PW 550

The PW 550 pallet changer combines the clamping method of the PW 500 with the length transfer of the PW 3000, thus preventing any cross-contamination.

more about it:

Pallet changer for clean room airlock

Now implement every application with the Baust hybrid pallet changer.

Inquire us now: