High quality pallet rotator and pallet spinner machines from Baust

Spin and rotate pallets made easy

A pallet rotator is a type of machinery used to rotate large wooden pallets. Pallet rotators are often used in factories and warehouses to move heavy objects from one place to another. They are also used in lumberyards and sawmills to move logs and other materials. Pallet rotators typically have a large arm that extends from the center of the machine.

A pallet spinner is a type of machinery used to rotate pallets, or heavy duty platforms, in order to move them from one place to another. Pallet spinners are often used in manufacturing and warehouse settings in order to quickly and efficiently move products or materials from one area to another. In addition to their industrial applications, pallet spinners can also be used in a number of other ways, such as for moving heavy furniture or for rotating items on display.

Pallets

- Total weight up to 1500 kg

- Standard pallet (W x L in mm): 800 – 1000 x 1200

- Max. Height incl. pallet: 2000 mm

- Overload tolerance per side: 50 mm

- Goods: e.g. cardboard boxes, barrels, crates or bottles

Other options

- Other pallet dimensions and heights

- Automatic pallet magazines

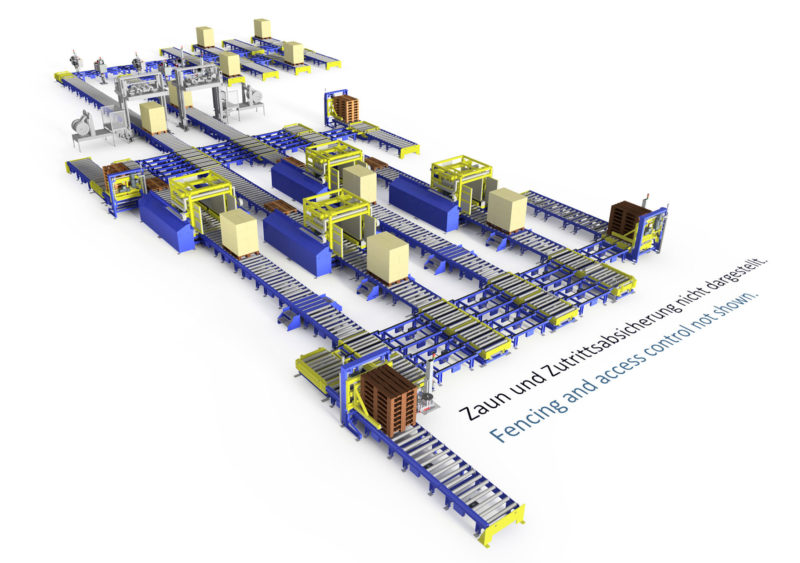

- Complete systems with automatic wrapping

Here is why you should use pallet rotators and pallet spinners for your company

There are many reasons why you might want to use a pallet spinner or pallet rotator. For one thing, it can help you to save space in your warehouse or storage facility.

By rotating the pallets, you can fit more of them into a smaller area. Additionally, a pallet spinner can help to prevent damage to your products. If your products are stored on pallets that are not rotated, they may become damaged due to uneven weight distribution.

By using a pallet spinner, you can ensure that the weight is evenly distributed, preventing damage to your products. Finally, a pallet spinner can help to improve the efficiency of your operations.

By rotating the pallets, you can reduce the amount of time that your employees spend walking back and forth between them. As a result, you can improve your overall productivity.

Request a non-binding offer now

Powerful pallet rotator

Baust’s pallet spinners are designed to simplify and automate logistics and transport operations in logistics. The pallet rotator offers the clamping method, the turning and kipping method and the overshifting method of pallets. They simplify the operations as it eliminates the need for people to drag, turn and stack the heavy pallets. This is much more time efficient and also less dangerous. The pallet spinner is very powerful and can perform the operations very quickly. Pallet rotators are a wonderful way to automate the repalletizing of robust goods, saving precious time and energy. The pallet changer is relevant to any industry. The point is to be able to work more efficiently. For example, in the pharmaceutical and food industries, high hygiene regulations are observed. The plaque spinner is characterized by the fact that the handling of the goods is very gentle and maintains a high level of safety.

The procedures of the pallet spinner

Even when it comes to shipping loaded pallets, the pallet spinner offers optimal solutions to make the procedures more efficient and cost-effective. In warehouse logistics, it is usually important to transfer products, correct their orientation or change their sequence. Since this, done manually, is very time-consuming, the pallet rotators is an optimal solution – without losing the gentle handling of sensitive goods. One of the processes, for example, is the overshifting process. Here, the pallet spinner can load a low pallet. This is a very gentle way of handling the goods if they are sensitive. This is all done in a much shorter time – the pallet spinner can perform up to 60 changes in an hour. This saves precious time in this logistical process. The turning and tilting process performs turns in case of unusual or irregular formats. In this way, the safety of the goods can be guaranteed even in case of overhang.

High performance with a wide range of goods

The pallet centrifugal can convince with high performance with the most different goods. In addition, the pallet spinner is very easy to operate and offers a trouble-free workflow at all times. The various functions ensure a smooth flow of materials and should not be missing in any logistical process. The clamping method, for example, is based on fixing the goods from two sides. This is advantageous for robust, pressure-stable goods that have no gaps. This can include cardboard boxes, beverage cartons or crates.

Clamping processes are often used for poorer pallet quality. This method can be integrated into the pallet spinner or used stand-alone in a material handling system. They offer fast, efficient and easy changing of pallets. The pallets are lowered above the pallet truck and then the pallets can be changed quickly and easily. In this process, the goods are neither rotated nor tilted. This modern method can perform up to 50 changes per hour. It is suitable for Euro pallets, plastic pallets, but also for one-way pallets.

Pallet spinner for smooth processes in the material flow system

The pallet spinner does the job for you quickly and reliably and ensures a smooth flow in the material flow system. The turning and tilting process also offers repalletizing by up to 135 degrees to the rear. In the process, individual pallets can also be tipped over and thus conveniently exchanged in height. Our devices can easily cope with different pallet sizes and even poorer pallet quality. Also in the case of the pallet rotator in the turning and tilting method, loading is carried out with a forklift truck or pallet truck, depending on the model. The pallets are held from 3 sides and then rotated or tilted. After that, the target pallet can be placed directly on the goods. The turning and tilting process is also ideal for simply replacing the pallet. Here, the pallet spinner offers maximum flexibility. Up to 40 pallets can be changed per hour, which again offers an enormous time advantage and makes the work processes very efficient.

Free initial consultation for the pallet spinner

Material handling systems offer a wide variety of solutions for different needs. We offer a free initial consultation to help you determine which equipment will be beneficial to your logistics processes. We promise to highlight and specify exactly which operations would offer you and your goods the most to save time, energy and money. With our technical expertise and many years of experience with a wide variety of industries, we can quickly put together the right products for your needs If you decide to work with us, we will offer you clean planning, production, installation and maintenance from our own hands. This is done in a fast and clean way. Our initial consultation is free of charge. Feel free to contact the experts at Baust and get an insight into the possibilities of our material flow systems. We are sure that with our concepts, products and ideas we can offer you a solution that will provide you with a lot of efficiency in the future and save you a lot of time and energy. We are looking forward to meeting you!