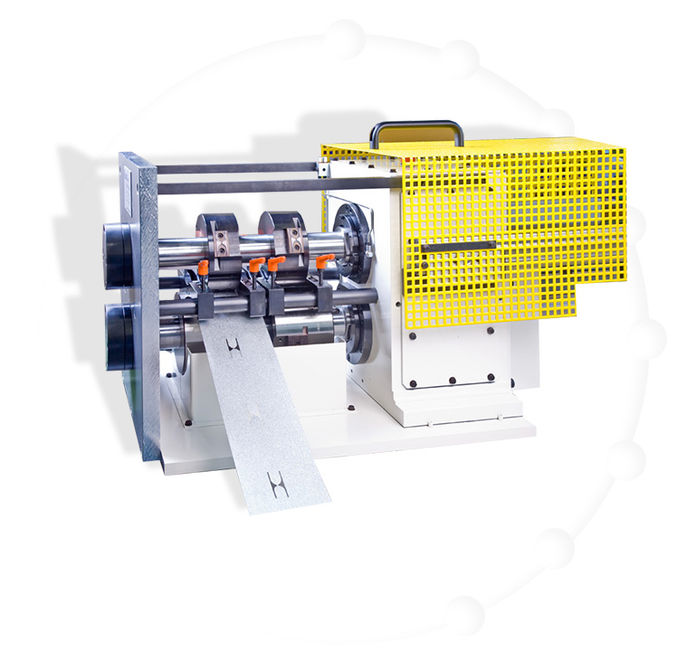

BRE-Series – Servo-driven Rotary Punching Insert

Rotary punching units are to be integrated directly into roll forming lines. In contrast to the BRS series, the profiling line takes over the material guide through the rotary punch slot. Immediately after the punching, the deformation can begin in the profiler. The rotary punch unit has its own servo drive, which is synchronized to the profiling line.

BRE Line configuration

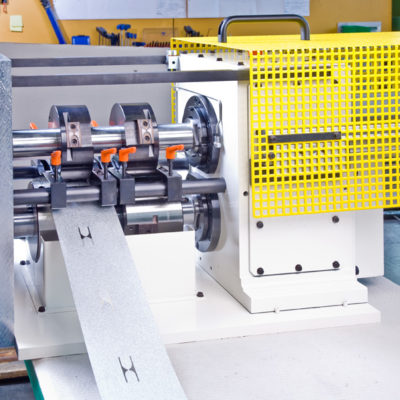

Baust manufactures the machine plug-in units with the corresponding removable plates according to the requirements of the profiling system manufacturer. The integration eliminates the space that is otherwise needed in front of the profiling line. The punching units can be integrated in the line or removed again if required. Thus, a higher flexibility of the line is given. The safe handling and high processing speeds as well as the simple and space-saving integration are just some of the advantages of rotary punching.

Request a non-binding offer now

Servo-driven Rotary Punching Insert for Roll Forming Lines

Our servo-driven rotary punching inserts of the BRE series integrate seamlessly into your existing roll forming line. The roll forming line takes over the complete material guidance, while the punching insert is exclusively responsible for precise punching operations. The dedicated servo drive synchronizes electronically with your main line and ensures exact positioning at any line speed.

We manufacture each servo-driven rotary punching insert individually according to your requirements with matching exchange plates for quick pattern changes. We process material thicknesses from 0.5 to 3.0 mm with tensile strengths up to 600 N/mm² reliably. Since 1981, we have been developing punching systems for the metalworking industry and have built up comprehensive expertise.

Efficiency Increase Through Space-Saving Punching Technology

By integrating our rotary punching inserts directly between two roll forming stands, you significantly reduce your space requirements. Production lines can be shortened by 15 to 25%, as separate pre-punching stations and intermediate buffers are completely eliminated. You can use the saved hall space elsewhere or save investment costs for new constructions.

Our servo-driven rotary punching inserts work with cycle times under 0.3 seconds per punching operation and enable line speeds up to 120 m/min. A measuring wheel in the roll forming line captures the strip speed and transmits it in real-time to the servo drive. We automatically compensate for accelerations and decelerations, so hole positions are maintained precisely even with variable profile lengths. You achieve throughput increases of up to 30% compared to lines with upstream punching stations.

Servo-driven Rotary Punching Insert with Synchronized Drive

The electronic coupling between your roll forming line and our punching insert is based on a master-slave control. We use modern servo controllers with resolutions of 0.01 mm and achieve positioning accuracies of ±0.1 mm across the entire profile width.

We monitor each punching operation via force sensors. The servo-driven rotary punching insert automatically detects deviations due to material thickness fluctuations or tool wear. Strip breaks or material double layers are detected and stopped within 50 milliseconds. The service life of the punching tools reaches 500,000 to 2,000,000 punching cycles with proper maintenance. We offer you service contracts with plannable maintenance dates that minimize your production downtimes.

Easy Handling Thanks to Modular Design

We also integrate our modular servo-driven rotary punching insert retrospectively into your existing roll forming line without extensive modifications. Standardized connection dimensions ensure compatibility with common roll forming stands from various manufacturers. We complete the installation between two forming roll stands including commissioning in two days.

Tool changes are carried out without tools via quick-clamping systems. Your operating personnel can exchange punching patterns in less than 15 minutes without having to dismantle the roll forming line. Exchange plates are aligned to the millimeter with positioning pins and fixed pneumatically. Repeat accuracy after tool changes is 0.05 mm. For product changes without punching requirements, the insert can be removed from the line within 30 minutes.

Continuous Material Processing Without Intermediate Buffers

Our servo-driven rotary punching inserts completely eliminate intermediate buffers and material loops. The material runs continuously from the coil through the punching unit directly into the profile rollers. This continuous material guidance reduces mechanical stress and lowers the risk of strip breaks or surface damage.

The absence of buffer systems significantly simplifies your line control. Tension monitoring and loop control are completely eliminated, which reduces sources of interference and increases line availability to over 95%. Profiles with length deviations under 1 mm are series standard. We have installed over 400 systems worldwide – from the automotive industry to electrical engineering to the building materials industry. This experience continuously flows into our further development.