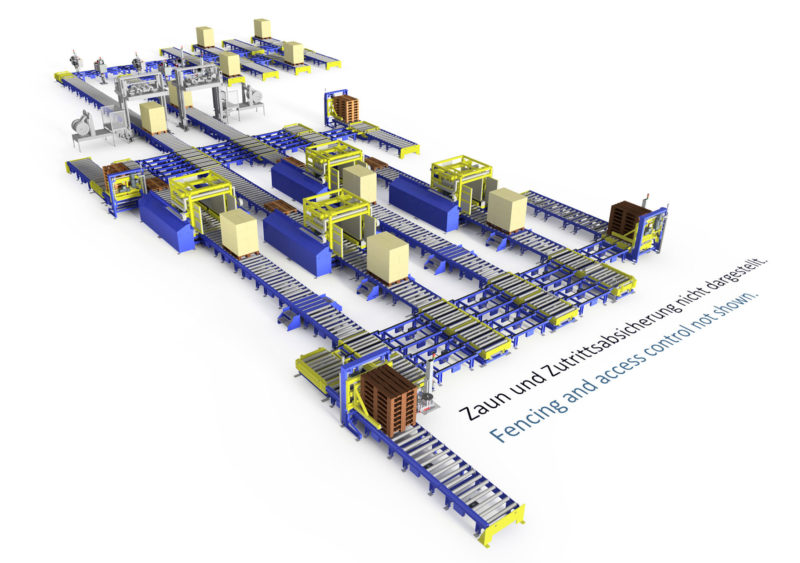

Pallet conveyor system for your automated material flow

A pallet conveyor system reliably transports goods through your production facility, warehouse, or logistics center. At Baust, you get pallet conveyor systems that are precisely tailored to your processes and connect all relevant stations with each other. From goods receipt to processing stations and pallet changers to shipping, our systems create a continuous material flow without manual interruptions.

Automating pallet transport brings measurable benefits to your business. You reduce forklift traffic, speed up throughput times, and minimize transport damage to your products. At the same time, you relieve your employees of heavy physical work and create safe working environments. Our pallet conveyor systems can handle loads of up to 2500 kg and achieve conveyor speeds that far exceed manual transport.

Configure modular pallet conveyor systems to suit your needs

Every business has different requirements for its pallet conveyor system. That’s why we rely on a modular design: we use standardized components such as roller conveyors, chain conveyors, corner transfer units, turntables, and lifting stations to configure individual pallet conveyor systems for your specific situation.

This modularity offers decisive advantages. You can start small and expand the system later as your requirements grow. Changes in the production layout can be implemented by reconfiguring the modules without having to purchase completely new systems. The integration of centering stations, pallet magazines, or disinfection locks is also seamless within the modular concept.

Everything from a single source, from engineering to installation

At Baust, you get your pallet conveyor system from a single source. Our engineers analyze your processes, create layout plans, and design each component to fit perfectly. Manufacturing takes place at our own plant in Langenfeld, where we also carry out pre-assembly and functional tests. Our technicians then take care of on-site installation, commissioning, and training your employees. This end-to-end process without subcontractors ensures quality and short response times.

Pallet conveyor system for smooth flow of goods

A well-planned pallet conveyor system eliminates bottlenecks and creates a continuous flow of goods through your operation. Instead of waiting for forklifts, pallets are automatically transported to the next station. Transfer carriages distribute the load to different lines, vertical conveyors overcome height differences, and buffer sections compensate for different cycle times.

The intelligent control system coordinates all movements and automatically optimizes throughput. Sensors detect the position and status of each pallet so that you always know where your goods are. In the event of a malfunction at a station, the system redirects pallets to alternative routes so that your material flow does not come to a standstill. This reliability makes pallet conveyor systems the basis for efficient complete systems in modern manufacturing and logistics.

Higher throughput with less personnel

Automated pallet conveyor systems increase your productivity in the long term. While manual transport depends on breaks, shift changes, and staff availability, a conveyor system operates around the clock at a constant rate. The investment pays for itself through savings in personnel costs, reduced forklift traffic, and fewer damaged goods. At the same time, you can deploy qualified employees for value-adding activities instead of repetitive transport tasks.

WORLDWIDE COMPANIES

that use pallets and trust Baust pallet changer & pallet turner