Palletizing systems automation | Palletizer | Palletizing machines | Complete Systems for material flow

Logistics know-how from a single source

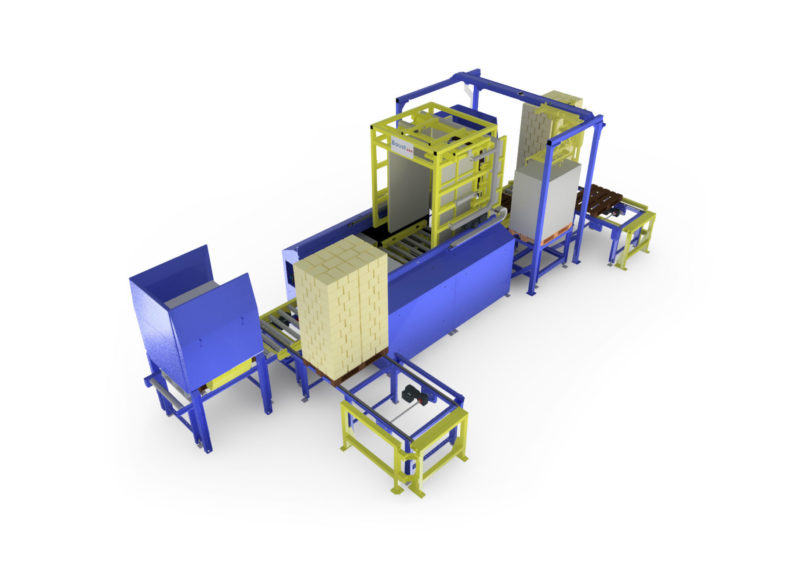

The experienced consulting team from Baust determines your individual requirements and recommends tried and tested solutions even for the most demanding tasks. Structures that are precisely tailored to the intended use ensure the integration of functional details in your system. A fully automated palletizing system and coordinated automation for the highest demands.

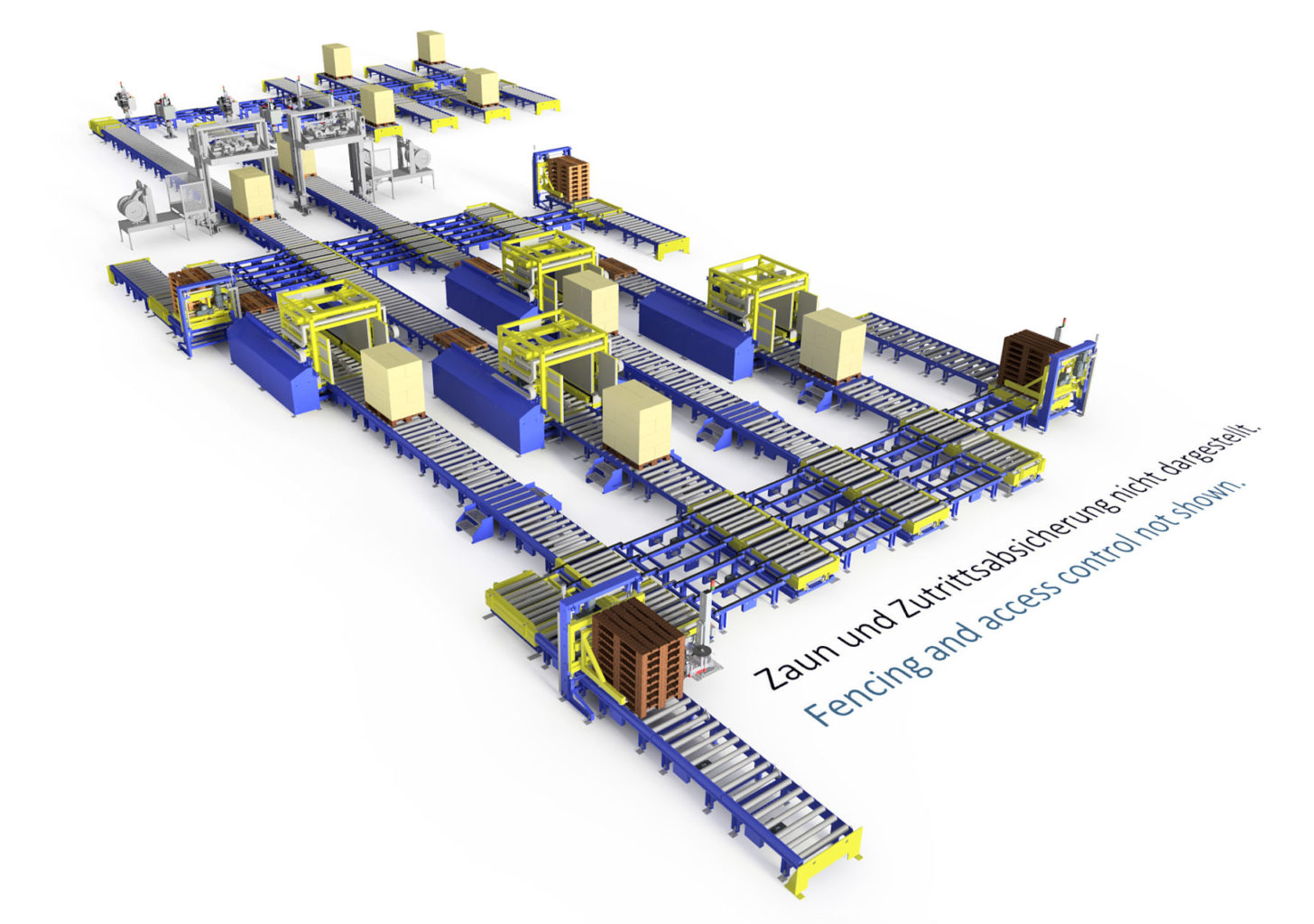

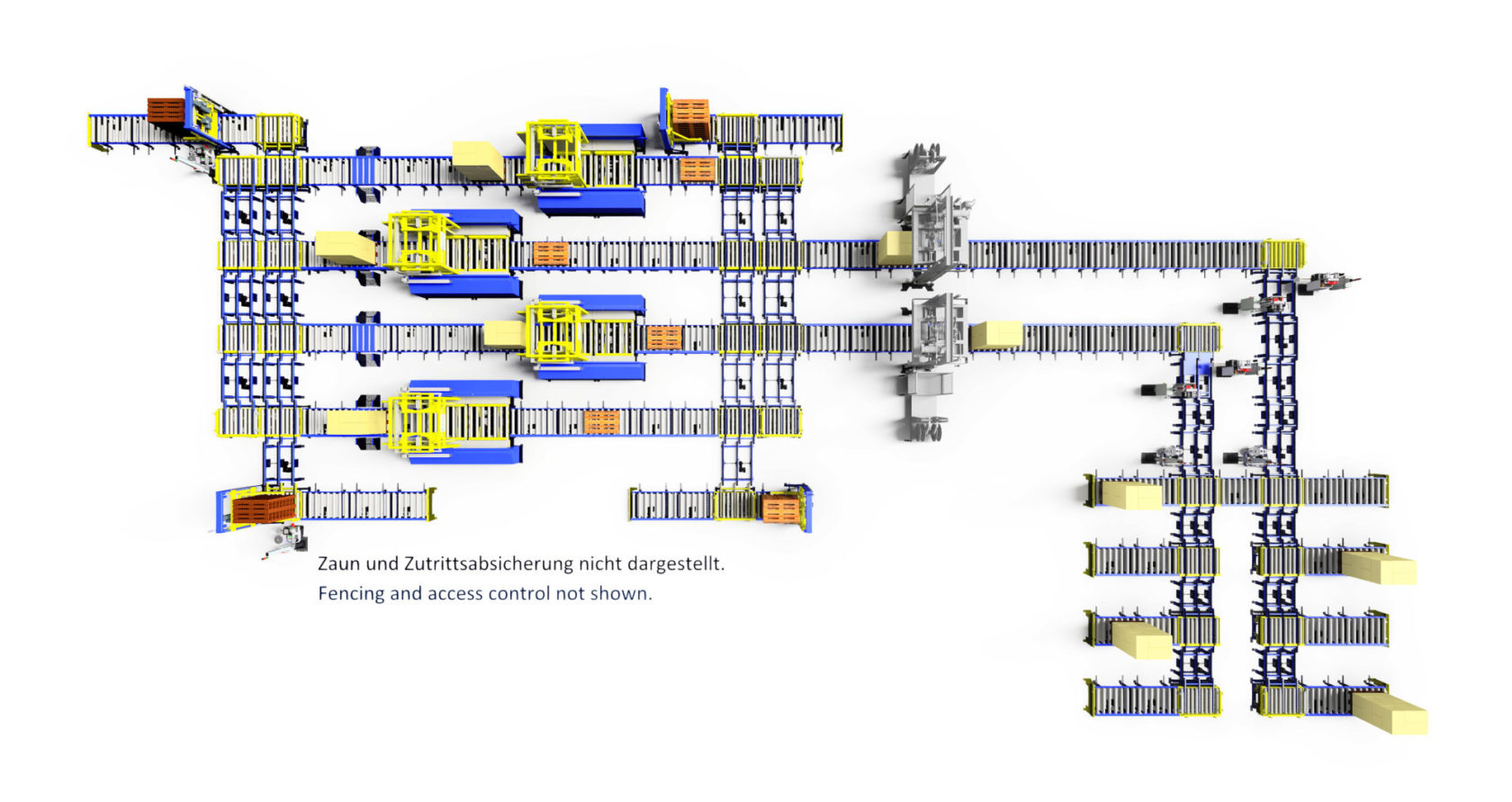

Palletizing systems automation: We plan your system with conveyor technology from a single source

The heart of our complete systems is always a machine for a specific application, which requires a great deal of engineering and know-how. The entire construction planning, development, production, testing and pre-assembly are carried out centrally at our site. You too can benefit from modern and qualitative palletizing systems.

Services that are available on request for all machines and systems:

- Consulting & project planning

- Conception

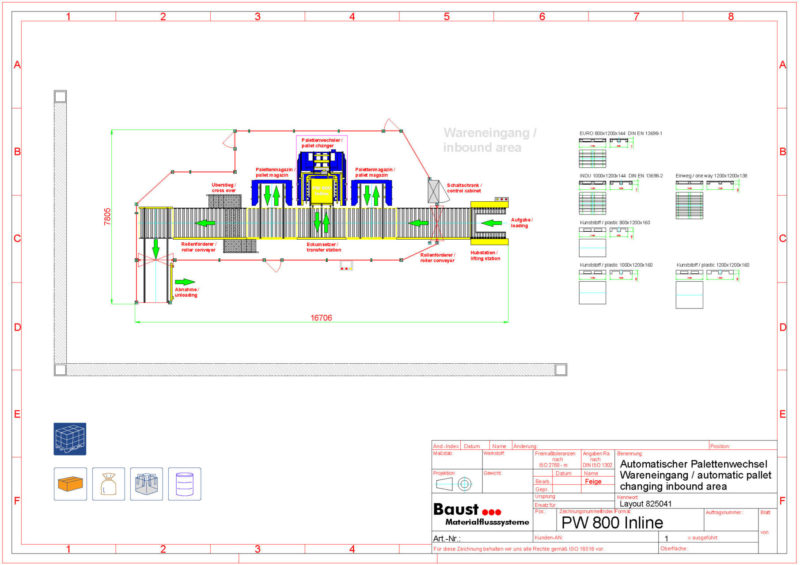

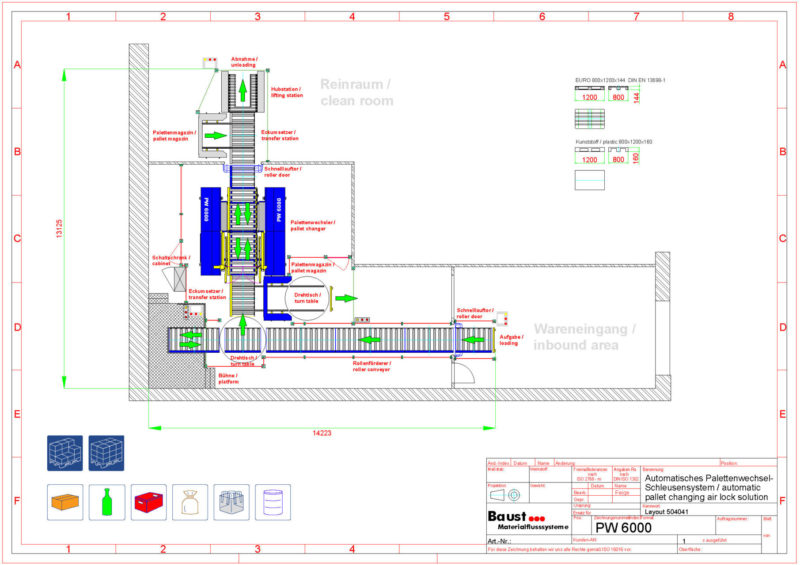

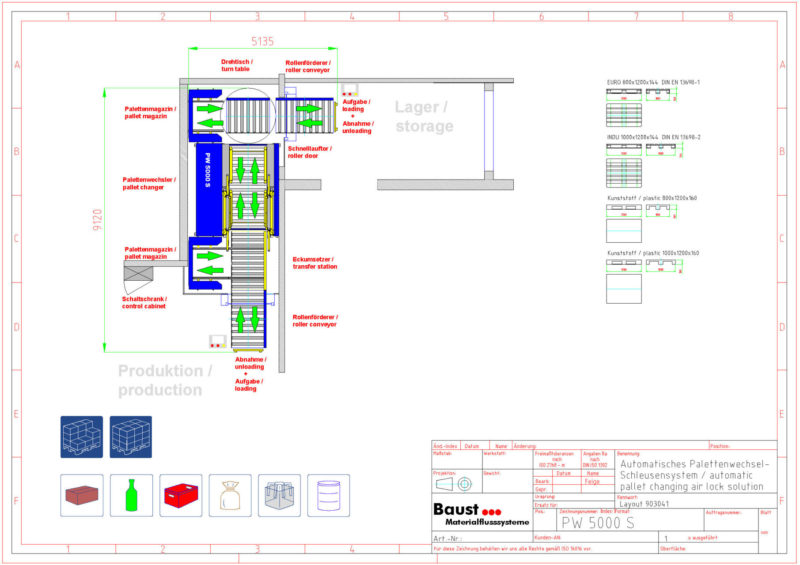

- Layout planning

- Cycle time optimization

- Control and programming

- Quality management

- Factory acceptance test FAT

- Installation, commissioning

- Final acceptance

- Training

- Aftersales management

- Service & maintenance

1

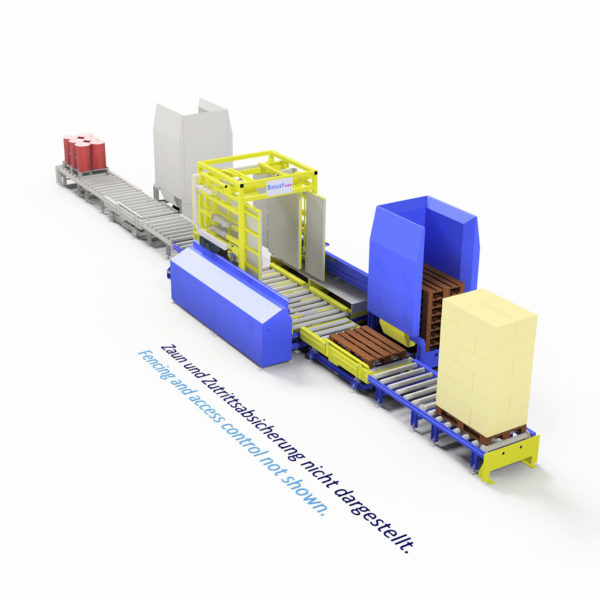

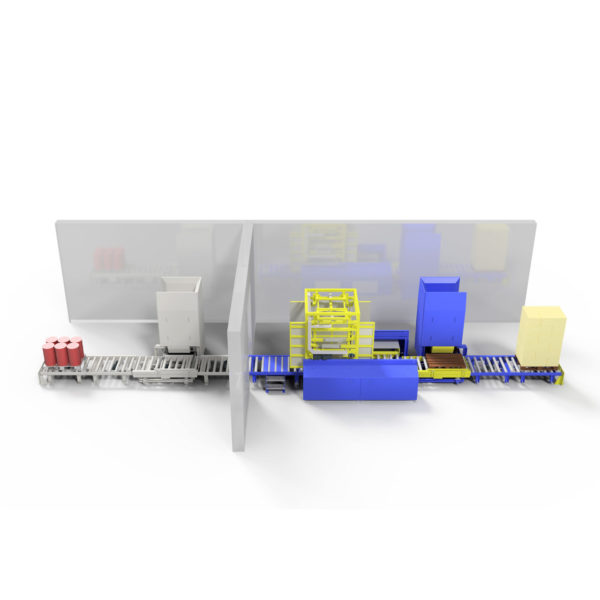

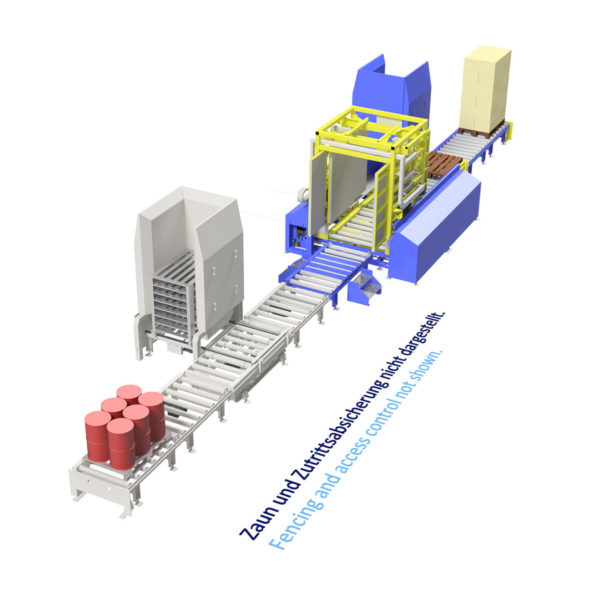

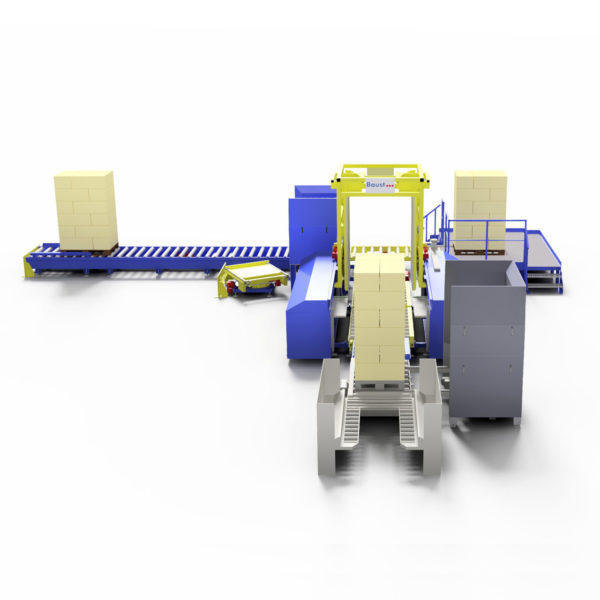

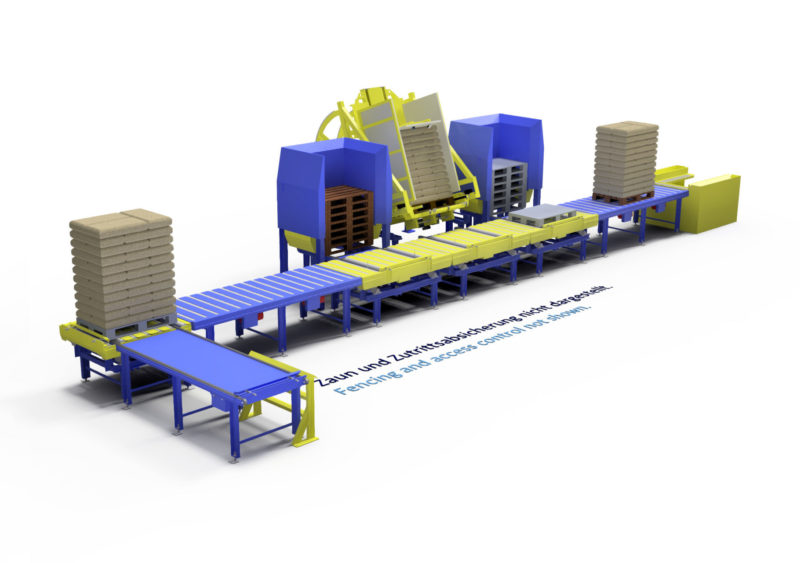

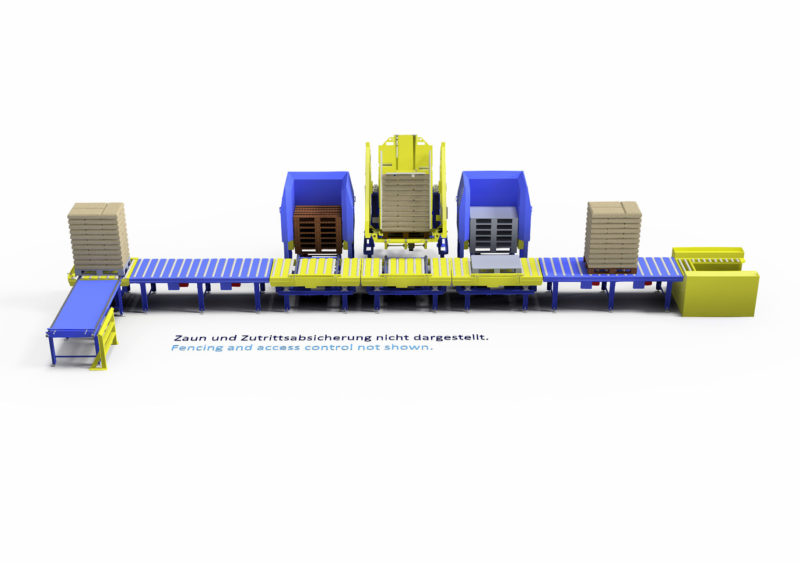

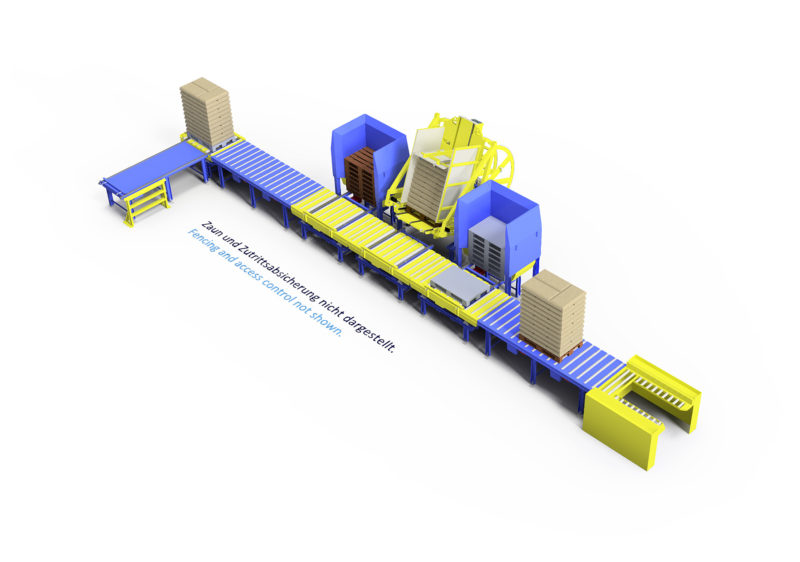

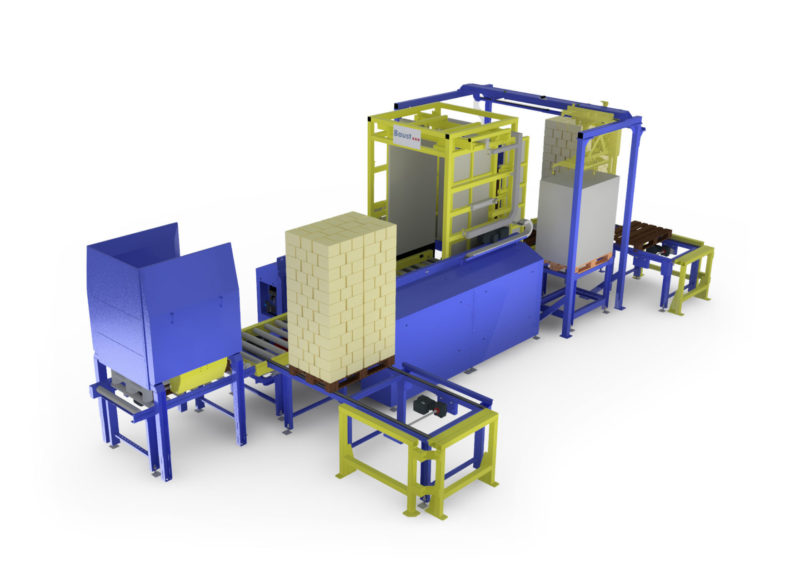

Depending on the process and application, a pallet changer / pallet inverter is used in one of the following processes:

- Clamping method pallet changers

- Inverting and Tilting method pallet changers

- Pushing method pallet changers

The possibilities are almost limitless thanks to our own engineering department.

2

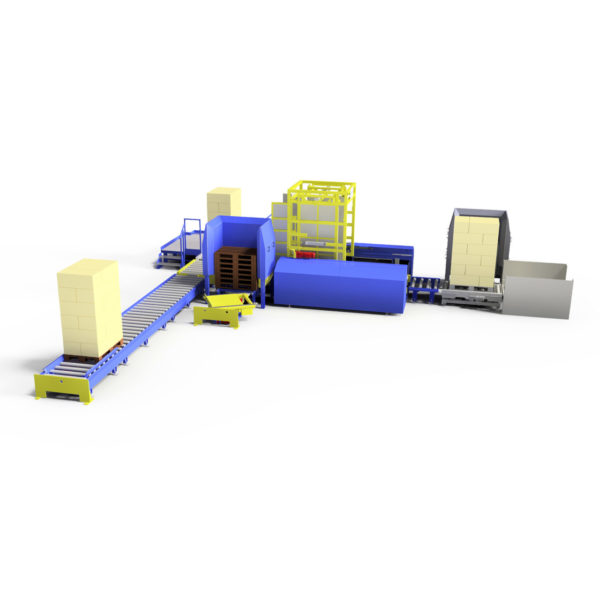

In addition to the automatic change of pallets, other processes can be carried out before or after:

In addition, a strapping, labeling, stretch wrapping or similar machine can be integrated into the material flow process.

3

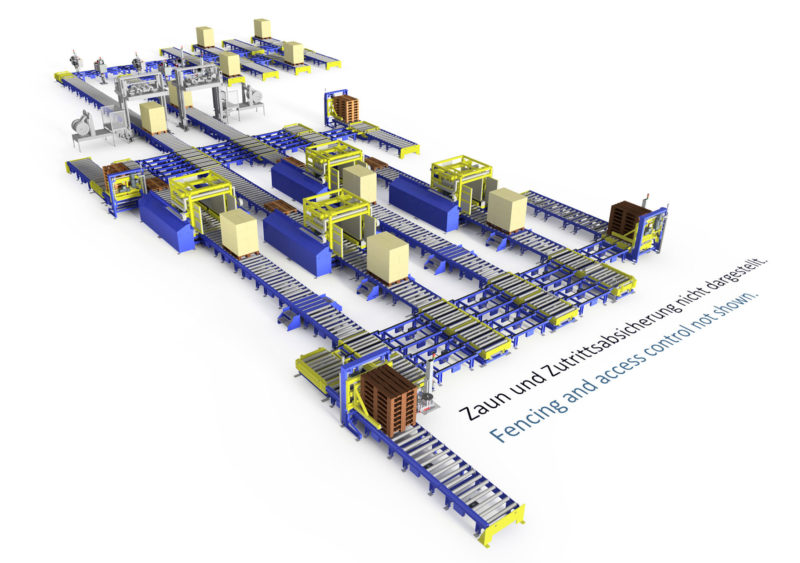

The connection between the machines is the surrounding conveyor technology, which we also develop, produce and integrate internally at the site.

One of our other core areas are precision rollers, drums and cylinders for mechanical and plant engineering.

4

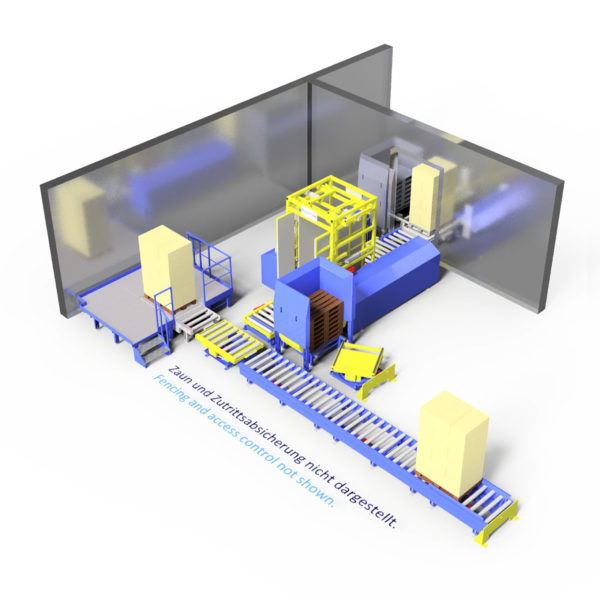

The scope of delivery of a turnkey complete pallet change system includes, among other things, ram protection, security technology such as fences and access protection by means of light barriers and secured doors as well as efficient material and process management with automation.

On request, we can also deliver these as a complete package, so that the system is fully operational.

Request a non-binding offer now for a BAUST complete / palletizing system

Fully automated palletizing system

We would be happy to advise you on all forms and variants of the fully automated palletizing machines and palletizing systems. Just give us a call or use our contact form.

Fully automated palletizing system from Baust – turnkey and optimally integrated

Specialized in the individual planning, construction as well as assembly and maintenance of the palletizing systems, we at Baust are the reliable and flexible partner who can even meet your unique requirements. Adapted for every industry and configured for every purpose, we provide you with a complete material flow system that you can design exclusively according to your needs. We support you with our specialist knowledge, experience and engineering skills in order to realize and test the palletizing system of your ideas. The integration of innovative pallet changers, sophisticated conveyor technology, selected functional details and other accessories make your palletizing system perfect. At Baust you get a competent solution from A to Z from a single source, consisting of the conception, cycle optimization to final acceptance and training. This means that the palletizing system can be commissioned without any problems and ideally tailored to your requirements.

The range of services for the palletizing systems

Depending on the area of

The high-quality main components for your palletizing system

At the beginning of the consultation, industry-specific record changers assigned to the areas of responsibility are presented, from which you can choose. Depending on the area of

Palletizing systems for your logistics project

In the next step, further process-related devices can be added and the method of the conveyor technology can be determined and supplemented with additional material. Upstream and downstream processes can be integrated for your material flow system and additional machines such as the centering station, the trolley, the pallet magazine and the film winder can be added. The palletizing system ensures optimal logistics management in your company and accelerates individual processes by connecting and combining them with efficient conveyor technology. Find the right one for your palletizing systems from the basic components such as roller or chain conveyors and turntables or corner transfer units. With Baust you receive technically experienced advice and future-oriented complete systems, which we combine with excellent service and aftersales management.