Baust Material Flow Systems | Conveying and storage technology

Your Partner for material flow systems and pallet conveyor systems

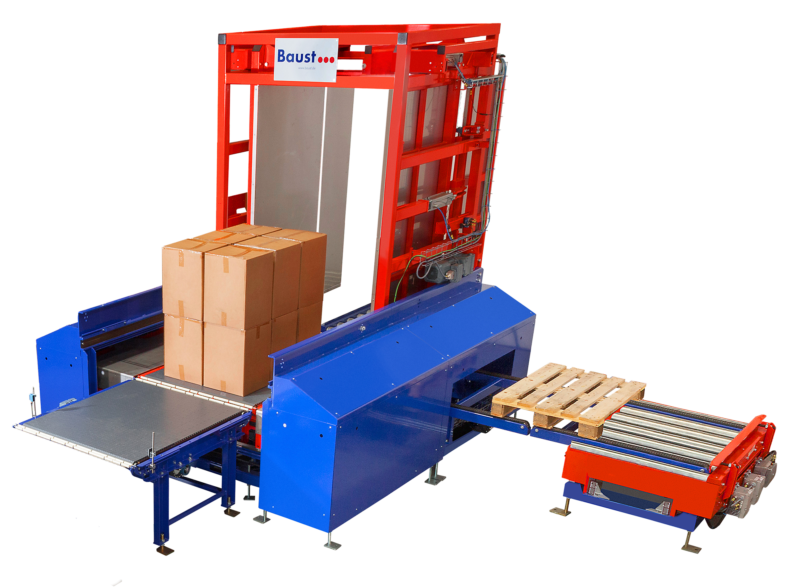

In order to do justice to the diverse requirements of effective transport and logistics management, Baust Material Flow Systems for material flow planning offer you the following products: pallet changers, all-sides centering stations, elevators, shuttle cars, drum palletisers.

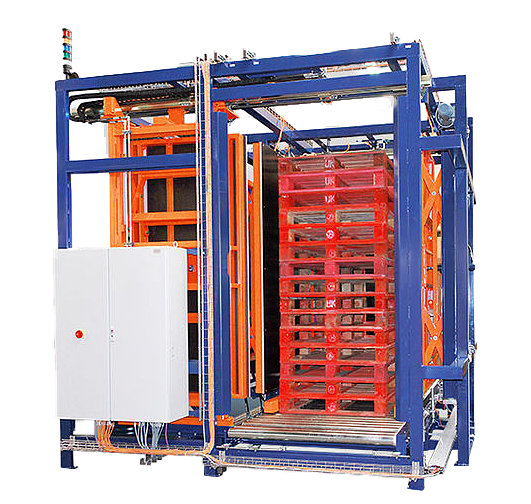

Our range of products is extended with products such as pallet magazines, pallet turners, pallet doublers, roller conveyors, chain conveyors, turntables, transfer units, lifting stations, centring stations, shuttle cars and control modules. You can see that the flow of goods and materials is secured with individual products and supported effectively.

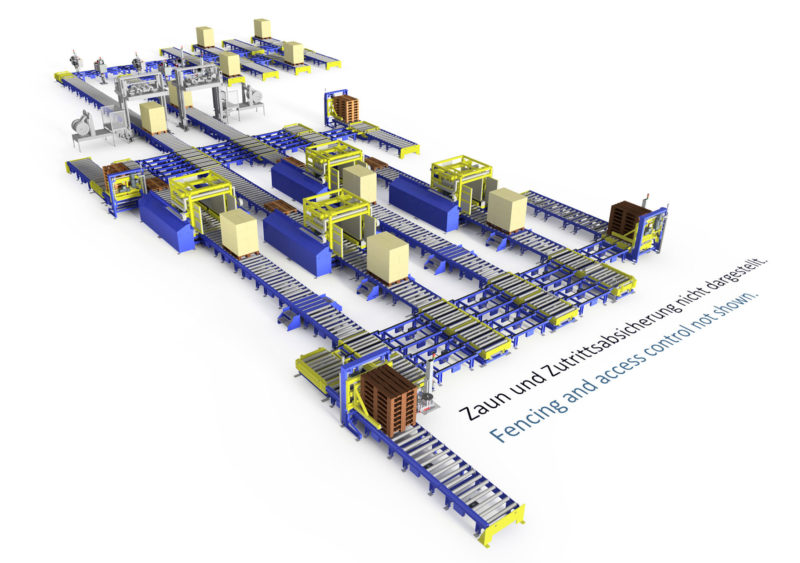

We also develop complete systems for material flow. We plan your fully automatic pallet changing process with conveyor technology from a single source.

Superlative! // Award-winning! // Fabulous!

Our Products

MATERIAL FLOW SYSTEMS

Engineering state-of-the-art

Baust products are reliable and innovative systems to increase your profitability. Individual solutions with extensive engineering based on a large modular system ensure continuous maximum performance in your processes.

Other products by Baust

Continuous product development and individual solutions made to measure

Often it is not the proven ways that lead you to success. Rather, it is the individual paths one takes to search for solutions that will advance you and your company and give you noticeable advantages in the market. Continuous product development is our passion, the exact implementation of your requirements is our competence. Take us at our word and challenge us!

APPLICATIONS & SECTORS

BAUST NEWS

Stay informed

WORLDWIDE BRANDS

who rely on Baust material flow systems

Material flow systems represent a logistics chain that starts with the supplier and ends with the customer. Baust supplies the appropriate technical components for smooth processes.

Baust supplies the appropriate technical components for smooth processes. Material flow or material flow systems represent a logistics chain that starts with the supplier and leads to the customer in the last step. Several processes are part of a material flow system, such as the extraction and processing of raw materials, packaging, warehousing to distribution to suppliers (distribution), as well as shipping to the end customer. Storage and transport are also important processes, where we develop and produce innovative systems in machine technology and plant engineering. In material flow planning, we offer reliable systems for many industries.

True to the motto “Engineering – state-of-the-art”, our products in the material flow system include:

- Pallet changer

- Palletizers & depalletizers

- Cover sheet applicators

- Pallet aligner

- Centering station

- Pallet doffer

- Drum palletizer

- Traversing carriage

- Pallet magazine

- Pallet turning station

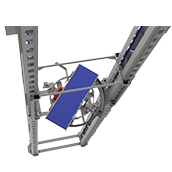

- Vertical conveyor

- Basic components

- Control equipment

Up to complete systems for material flow in the form of semi-automatic or fully automatic palletizing systems. These internal material flow systems ensure the transport of various materials and goods within the company. Lift trucks, forklifts or modern conveyor technology are classically used for transport.

Service providers offer appropriate material flow planning and material flow analysis to optimize these workflows and processes. Here, internal as well as external components are examined and a corresponding optimization is developed. The results of the material flow analysis provide the company with important information about the efficiency of the company and possible process errors and weak points in the process chain. Specialists and managers can initiate changes on the basis of this analysis and thus optimize the processes in the warehouse and logistics.

Baust material handling systems are accordingly the ideal component for efficient, reliable and safe conveyor and storage technology worldwide. With our hybrid pallet changers, several processes (clamping, turning/tipping & pushing) can already be combined in material flow planning. This saves space, increases utility and reduces investment costs.

Palletizers & depalletizers for automatic palletizing of Baust also offer further advantages as high-performance processes for effective intralogistics.

Let us advise you on your material flow system without obligation.

Pallet Conveyor Technology: What are Material Flow Systems?

Material flow systems are integrated systems that track the flow of materials from a source to a finished product. They help organizations to optimize existing material requirements, inventories and resource efficiency while reducing waste. Material flow & conveyor systems provide an integrative view of the entire supply network, enabling companies to establish local efficiencies using insights into material flow at every corner of the supply chain. Material management can be made more efficient and sustainable without compromising on customer service. This principle ultimately translates into cost savings and productivity gains for businesses in today’s competitive market.

Material Flow Systems: What is Pallet Conveyor Technology?

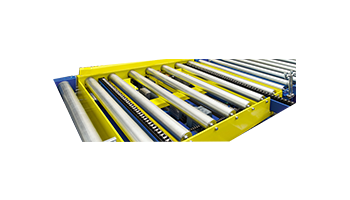

Pallet conveyor technology is an important part of the material flow system. It refers to the conveyance of pallets, containers and similar load carriers on a specified transport route. A material flow & conveyor system uses different types of conveyors such as roller conveyors, chain conveyors and pallet boxes to transport goods efficiently. This technology helps companies and organizations to control the movement of products faster throughout the facility, from production to shipping.

Pallet Conveyor Technology for an Efficient Process

Material flow and conveyor systems offer an efficient solution for material transport in production and logistics environments. The pallet holder makes it easier to insert and eject pallets by preventing deformation during the handling process. With this equipment, the flow of productions can be significantly improved, since pallets can be moved through processes more quickly. The step drive based pallet row allows automated transition of pallet types and serves as a safer alternative to manually operated conveyors as less effort is required. This minimizes manual travel time and improves overall efficiency, creating a safe and productive operation.

Disinfection Locks as a Supplement for Material Flow Systems

Disinfection hatches offer a useful addition to material handling systems to improve efficiency and protect sanitary integrity in sensitive environments. Our disinfection locks work with UVC rays for effective sterilization. Disinfection locks offer a reliable solution and quality assurance for hygiene, especially in areas where people come into direct contact with food processing material or where sensitive biological components have to be transferred through the material flow system.

Cover Sheet Feeder for Automated Logistics

Top sheet feeders ensure that material flow systems function efficiently in complex logistics operations. These special trailers are placed on pallets and automatically monitor the flow of deliveries within the logistics process. Cover spreaders provide accurate data on order history, freeing workers time for other important tasks. Logistics experts can identify potential savings by making optimal use of transportation. Top sheet feeders are indispensable technology for ensuring efficient logistics processes and supporting seamless integration across the supply chain.

Pallet Aligner in the Material Flow System

Pallet aligners are an essential part of material handling systems in industrial settings. They are used in warehouses and factories to position pallets safely and efficiently to facilitate circulation. Pallet aligners automate the processing of pallets at destination while minimizing downtime when handling heavy pallets. This equipment improves the overall flow and reduces manual intervention. There are different types of pallet aligners with customizable features to match different facility requirements.

Pallet Doubler in the Material Flow

Pallet doublers are an efficient way to manage material flows in manufacturing environments. This computer controlled device automatically moves pallets from one station to the next and allows changeover operations such as splitting and assembling pallets within the pallet handling system. Pallet doublers significantly reduce time required as the switch from manual handling to automation has been made. It saves labor and increases productivity and overall safety of pallet operations. This autonomous equipment represents a key part of optimization in the material flow system.

What are Conveyor Carriages?

Transfer carriages form a central element of modern material flow and conveyor systems. They transport goods over shorter and longer distances within the facility. Transfer cars are versatile in terms of type and size of loads they can carry and are available for special tasks in industrial applications. Modern transfer cars are equipped with tracking systems and optional features such as drive systems or on-board computers. Transfer cars enable companies to use hardware in the best possible way with an efficient workflow of the entire material flow system, supporting both planning and execution.

Pallet Conveyor Systems and the Vertical Conveyor

Elevated conveyors are a very efficient way of transporting materials in modern material handling systems. They are mainly used in automotive, small parts and electronics industries for production applications. Vertical conveyors are used in the vertical connection area of production lines and warehouses. Drop chain conveyors are quiet, energy efficient and require little maintenance, making them an excellent choice for companies looking to improve their material flow system. The conveying process can be adjusted to given requirements with variable speed control. Vertical conveyor technologies represent an essential component of modern material flow systems, supporting efficient material flow from assembly through to final transportation stages and streamline the environment for continued success.