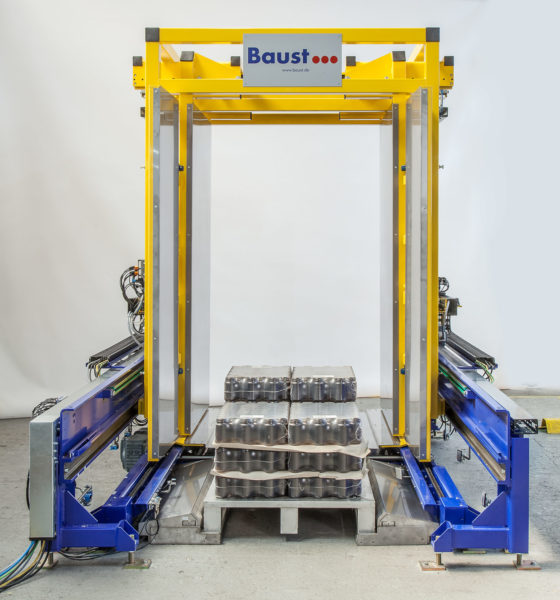

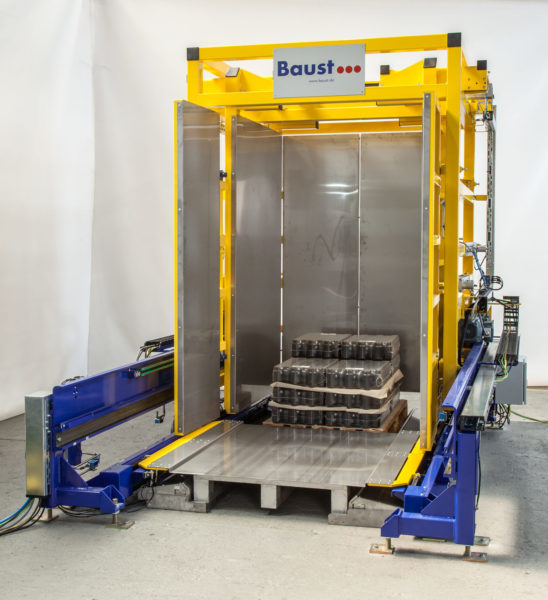

PW 3000 LS impresses with its small footprint and meets all hygiene requirements for airlocks between hygienic zones.

The exchange of pallets between two cleanroom zones always means a challenge: the goods have to be moved in a very limited space while avoiding cross-contamination. There are strict hygiene regulations, the rooms are strictly separated. At the same time, the goods are often sensitive. Raw materials have to be fed into production, finished products have to be transported from the clean room to the warehouse. Often, other tasks such as packaging, disinfecting or taking samples also have to be performed. High-speed doors and an overpressure control system ensure a controlled air flow into the warehouse or logistics area.

PW 3000 LS – perfect for hygienic airlocks

The PW 3000 LS pallet changer not only meets all these requirements, but also requires very little space. Compared to conventional systems, it saves around 40% of floor space. Thanks to its lengthwise sliding sheet, it can also safely repalletise sensitive goods. This makes it perfect for all requirements of pharmaceutical, food and cosmetics companies. It is easy to operate from both sides. Options such as a complete design in stainless steel according to GMP standards and the consideration of explosion protection requirements complete the range.

More information about the PW 3000 & PW 3000 LS models can be found here: